Webinar: Industrialization of Metal Additive Manufacturing in Automotive

October 01, 2020 Location: Online-Event

We are the leading provider of metal additive manufacturing systems and applications development for metal prototype and part production.

Our mission is to flatten the learning curve of metal additive manufacturing by providing high performance equipment, products, and know-how focused on maximising the benefits of selective laser melting technology.

3D printing metal has increasingly become a cost-effective manufacturing alternative for countless applications across a myriad of major industries. SLM Solutions takes a vested interest in your company’s long-term success with metal AM, providing support and knowledge-sharing that elevates use of the technology to the next level. Choosing the right technology is critical, but forging partnerships with the right AM provider is the fastest path to success.

Partner with SLM Solutions.

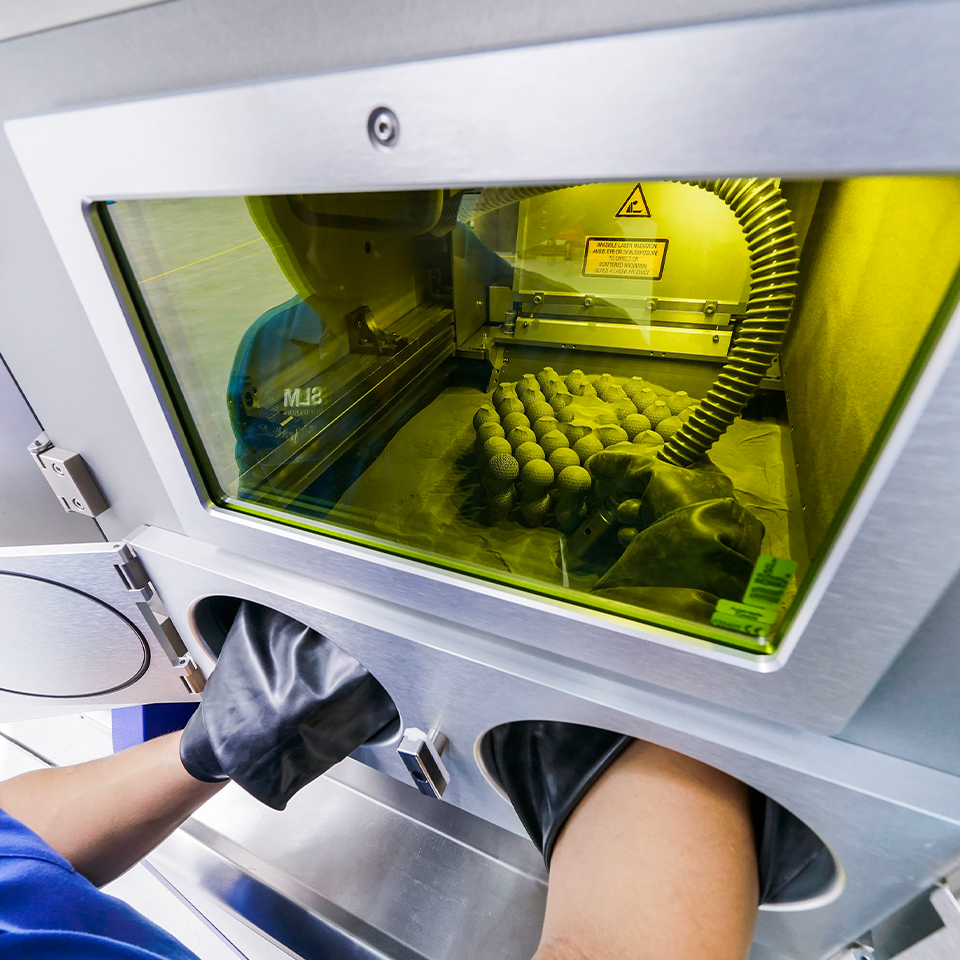

Selective Laser Melting machines from SLM Solutions feature multi-laser options, bi-directional recoating and closed-loop powder handling to achieve best-in-class safety and increased build speeds for complex and completely dense metal parts.

SLM Solutions provides a range of highly qualified metal powders and unique parameter sets to guarantee SLM® machines are running at peak performance.

To make your purchase decision easier, we offer various services, like benchmark production, job shop solutions or trainings. After your purchase our team ofexperienced field service engineers around the world ensure that your system stays up and running at peak performance.

As the inventor of selective laser melting and pioneer of metal additive manufacturing, SLM Solutions is the leading provider of industrial metal 3D printing machines. With a strategic focus on metal additive and multi-laser technology our selective laser melting machines are designed to be productive, reliable, and safe while maximizing operator investment. As the technology pioneer, we create endless possibilities to change the future of manufacturing forever.

SLM Solutions was first in the metal additive industry to offer multi-laser systems, bi-directional recoating and more. Today we continue to be completely focused on metal selective laser melting technology and propelling the technology forward.

SLM Solutions holds over 100 patented innovations that increase metal additive technology productivity and quality. Exclusive features such as bi-directional recoating, multi-laser overlap strategy, laminar gas flow and more make SLM® machines some of the most advanced on the market.

From its humble beginnings, SLM Solutions has grown to a 400+ person, publicly traded company with key locations across the world to serve a global customer base.

SLM Solutions' founding members are directly responsible for the invention of selective laser melting technology. We continue to focus on the development and distribution of the most innovative, production-oriented metal additive manufacturing systems.

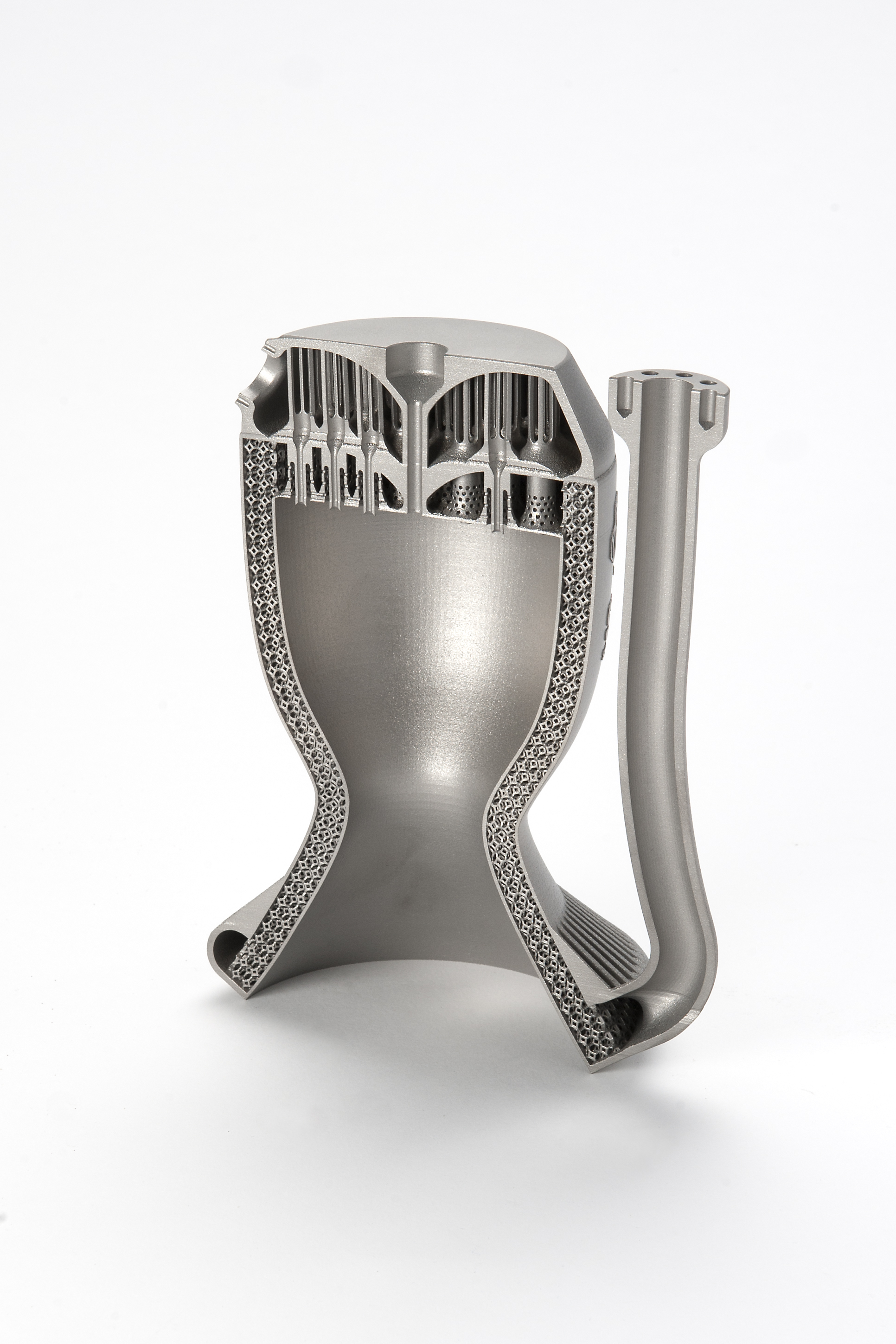

Additive Design Optimization with CellCore GmbH

Industry: Aerospace

Material: IN718

Layer Thickness: 30 µm

Build Time: 3d, 5h, 34 min (full load 1 piece)

Improved function:

Cooling through integrated lattice

Weight reduction with structural support lattice

Process Optimization:

Assembly reduction of multiple individual parts into one

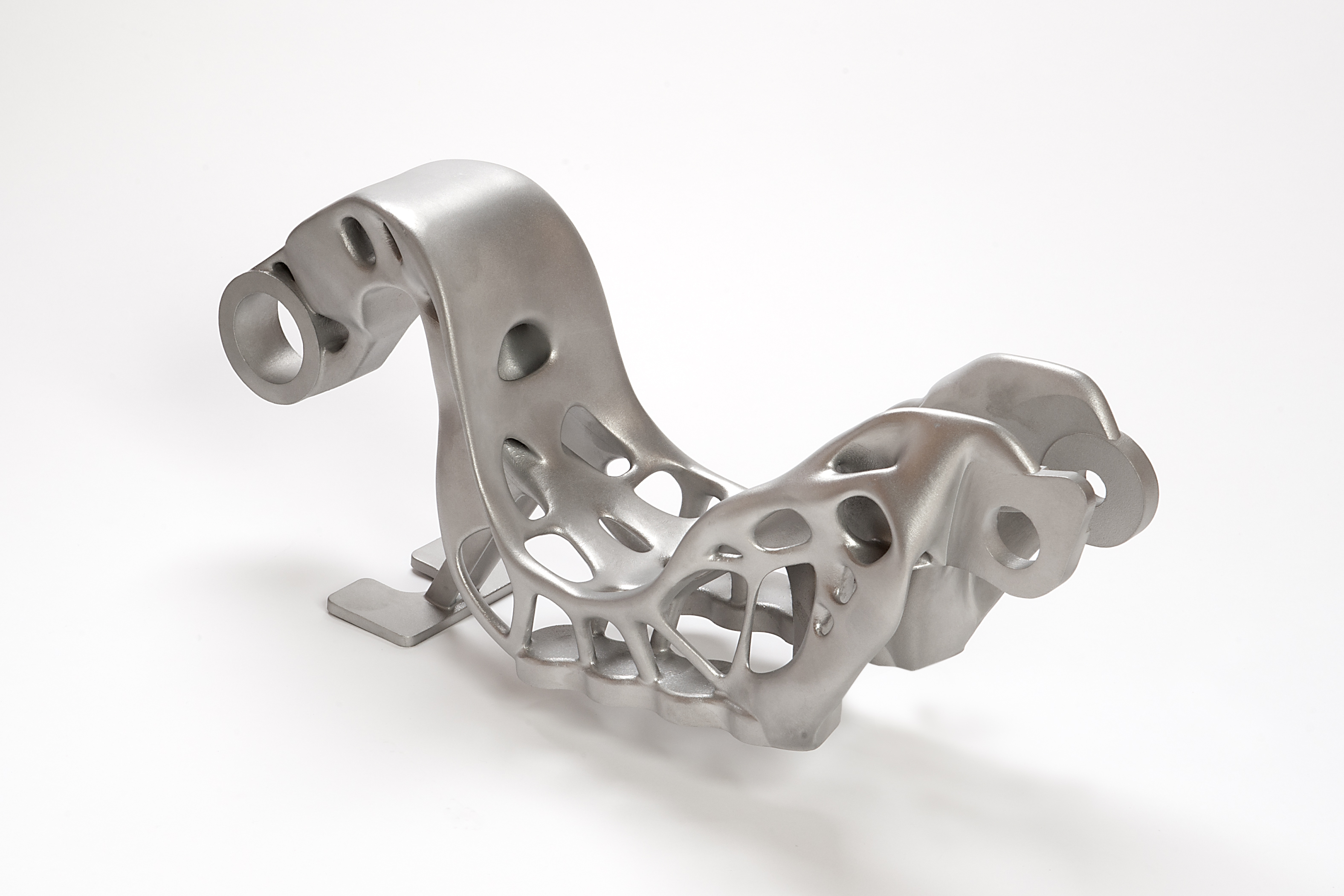

Component optimization at Asco Industries in the course of the AfloNext project

Industry: Aerospace

Material: Ti6Al4V

Layer Thickness: 30 µm

Build Time: 1d19h11min (full load, 2 pieces)

Reduced Buy-To-Fly-Ratio and significant reduction of machining time

Significant weight reduction and reduction of assembly time

Reduced assembly construction to reduce costs using the SLM® technology

Material: AlSi10Mg

Layer Thickness: 60µm

Build Time: 20h (full load, 10 pieces)

Improved Function:

Increased flow performance and 70% weight reduction

Efficient production:

45 % manufacturing cost reduction

Reduced Assembly:

18 individual components combined into one

SLM Solutions is a leading market provider of metal-based additive manufacturing technology. As an inventor of the selective laser melting process, we focus on the development and distribution of the most innovative, production-oriented metal additive manufacturing systems.

SLM Solutions offers an extensive product and service portfolio for manufacturing complex metal components with the aid of SLM® technology for its customers active in the aerospace and automotive industries, the energy sector, toolmaking, the medical sector and research and development.

Depending on the application, Additive Manufacturing can lead to numerous commercial and technical advantages that allow companies to strengthen their competitive position.