Additive Manufacturing

“Depending on the application, Additive Manufacturing can lead to numerous commercial and technical advantages that allow companies to strengthen their competitive position.”

Ralf Frohwerk, Global Head of Business Development of SLM Solutions

Additive Manufacturing and Selective Laser Melting

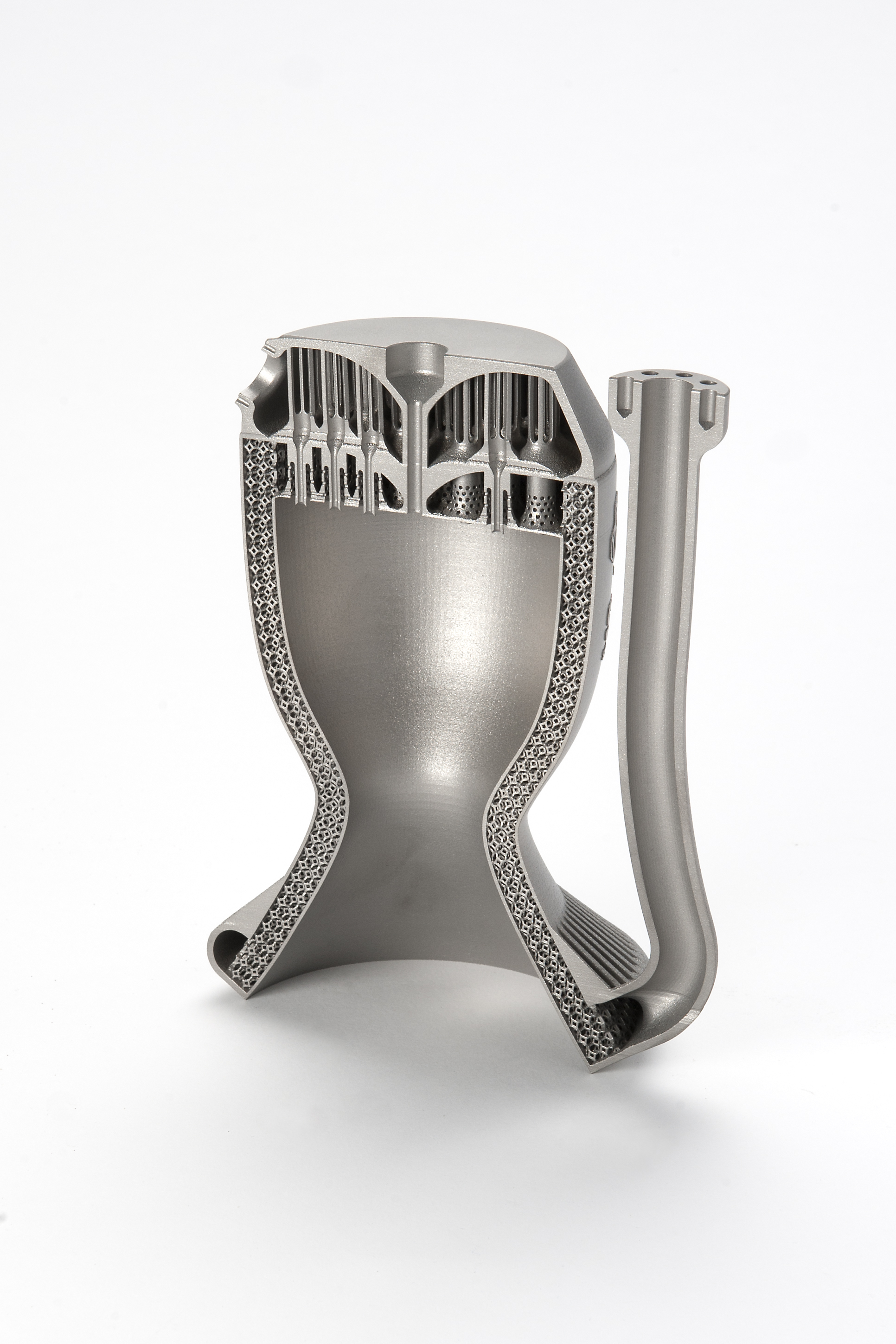

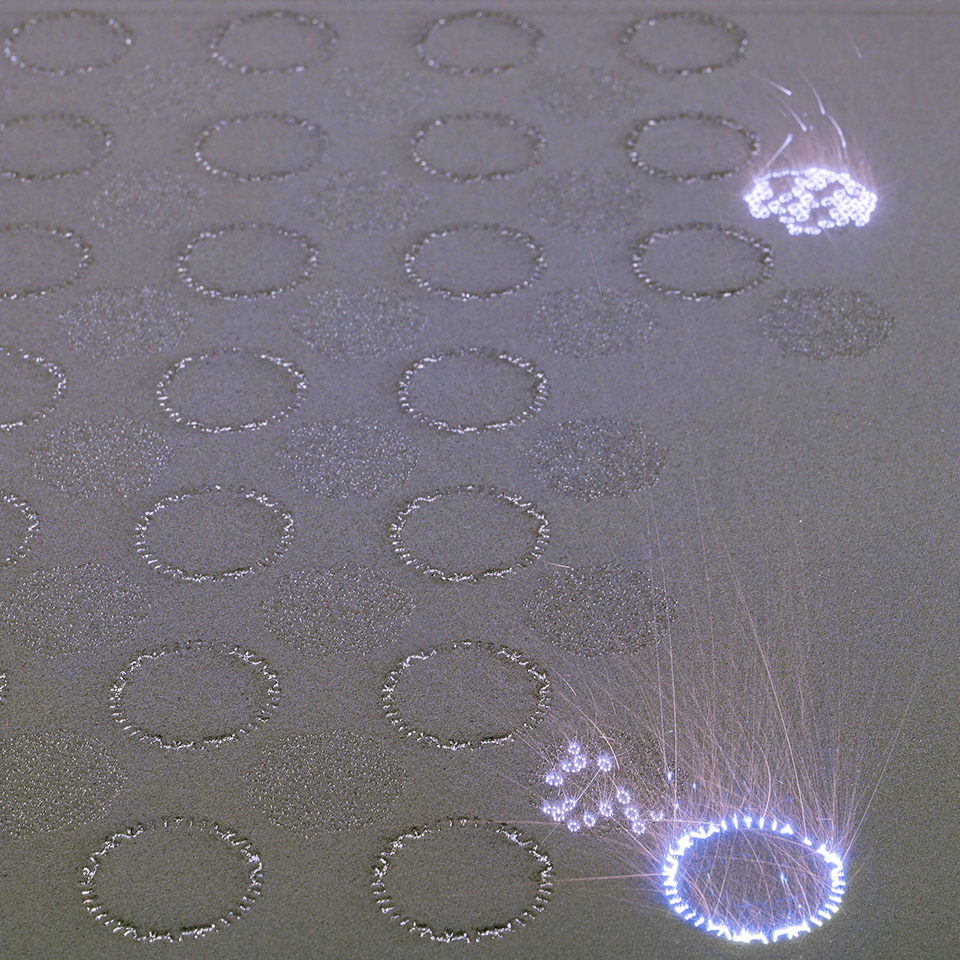

There are several different processes in the world of additive manufacturing, however, they are all based on the same principle of adding material to create opposed to traditional methods that subtract material. SLM Solutions is one of the inventors of selective laser melting technology and focuses on multi-laser metal additive manufacturing. SLM® technology is most concisely described as an iterative process that uses high powered lasers to melt metal powder along pre-defined pathways.

In selective laser melting an initial layer of metal powder is spread onto a substrate plate, then the laser selectively melts the powder to create the first layer of the build. A fresh layer of metal powder is then evenly distributed over the build surface and the lasers melt each successive layer to the layers underneath until the desired component is produced.

Data taken directly from digital CAD files is converted into individual vectors which the laser will traverse during each layer’s exposure. Unlike laser sintering, selective laser melting completely melts each layer into the previous for completely dense metal parts. Compared to traditional manufacturing methods, additive manufacturing enables parts with complex geometric shapes and hollow structures to be produced and is used in several industries such as aviation and aeronautics, automotive, energy, tooling, medical and dental, as well as research and development.

Advantages and Benefits of Additive Manufacturing

The enhanced level of design freedom afforded by metal AM allows for component consolidation, reducing multi-part assemblies into single parts. This capability considerably reduces supply chain risk and leads to higher productivity and efficiency.

Whether it is integrated cooling channels for better cooling or an entire process optimization by combining assemblies, Metal AM can lead to improved function at reduced material consumption and reduced weight.

AM design freedom allows for considerable weight reduction of components, resulting in enhanced fuel efficiency and reduced operational costs. Coupled with our system’s proven capability for full scale production, this re-design capability is a revolutionary advancement for different industries like aerospace or automotive.

In the early development stage, engineers are no longer constrained by traditional machining capabilities. The ability to rapidly prototype provides engineers the flexibility to adjust, optimize, integrate, adapt and otherwise improve their designs on the fly, resulting in early product improvements while reducing the cycle for new product introduction.

Industry Success Stories

Additively manufactured parts are already today produced in series production for different industries like aerospace, automotive, energy, tooling or in the healthcare sector. Depending on the application, additive manufacturing can lead to numerous commercial and technical advantages that allow companies to strengthen their competitive position.

Read some of our industry success stories below.

How to get started with Additive Manufacturing

Additive manufacturing technology delivers many benefits for complex metal part production. Before investing, companies need to balance technical requirements with the accessibility of metal AM expertise, and aligning with a solution provider that will function in a collaborative role. By partnering with SLM Solutions to bring metal AM capabilities in house, businesses gain a considerable advantage to immediately leverage the technology for optimal output. Here is an overview of the most important aspects to consider before investing in metal additive manufacturing.

LET'S CONCENTRATE ON YOUR APPLICATION

First our team of experts will focus on understanding your application. We will discuss how you want to use additive manufacturing and what metal parts you want to print. We will help you identify any opportuinties to leverage selective laser melting capabilities to achieve your AM goals such as:

- Part design for lightweighting, reduced post processing etc.

- Reducing multiple components into one part

- Part positioning and nesting to maximize build production

FACILITY CAPACITIES

After a thorough understanding of your application needs, next we will review your facility and assist in creating the ideal site for your SLM® machine. To create a turnkey experience we also offer all the SLM® machine support equipment like external chillers, powder sieves and post processing machinery. We can even assist with factory acceptance tests or individual side acceptance tests to ensure that your production meets or exceeds industry standards.

AM KNOWLEDGE DEVELOPMENT

Additive manufacturing requires an educated and knowledgable team to keep your production running smoothly. This is why we offer a variety of extended training and consulting packages curated by our metal AM technology experts. Our diverse team of experts stand ready to directly facilitate your AM implementation journey; assisting with design evaluations, facility and workflow optimizations, industry qualifications and more.

Directly impact your overall success by taking advantage of our experience to develop your team's capabilities and achieve your metal AM goals.

What you need for Additive Manufacturing

Metal additive manufacturing needs powerful, safe and productive machines that provide and maintain high part quality.

SLM Solutions focuses on the development and distribution of the most innovative, production-oriented metal additive manufacturing systems. We were the first manufacturer to offer overlapping multi-laser machines and continue to hold exclusive patents on our overlap stitching strategy, gas flow, and bi-directional re-coating system. Being some of the safest on the market, SLM® machines feature closed-loop powder handling, permanent filters, and even in-chamber vacuums so you do not need to open the chamber door to remove powder from a build. These features, and the continuous development of selective laser melting products, make SLM Solutions’ systems the most productive selective laser melting machines on the market.

Metal additive manufacturing machines require support equipment such as an external chiller and powder sieves. Additively manufactured parts need post-processing equipment to be prepared for use.

External Chiller

The external chiller, which is needed to cool the laser and optics, is often placed in a seperate room from the additive manufacturing system because it produces noise, heat and humidity. The chilled water is piped to the selective laser melting machine and there are requirements for the minimum size and maximum rise of these pipes.

Powder Sieve

The powder sieve is used to process the unmelted powder after each build, separating the small particles that can then be reused in subsequent builds from larger particles and contaminants which are typically disposed.

Post Processing Equipment

Post-processing equipment is necessary to remove parts from build plates, perform heat treatment and inspect parts. A bandsaw or electrical discharge machine (EDM) is used to remove parts from the build plate. Build plates can be finished with a small machining center, milling machine or grinder. Another option is to outsource the task to a local machine shop, but this option requires a larger plate inventory.

The raw material in the selective laser melting process is metallic powder, usually in the particle size range of 5 to 45 microns. A variety of alloys are available for additive manufacturing, but they must be weldable to be used in selective laser melting.

SLM Solutions has developed a specification and supply chain for a range of approved metal powders that ensure SLM® Systems produce components of consistently high quality time after time. We provide precisely engineered process parameters matching every offered material for SLM® machines, which enables additive manufacturing of high-quality components designated for technical applications.

To successfully use additive manufacturing, a deep knowledge in part design, called design for additive manufacturing (DFAM) is necessary. Rethinking applications, adding functions or the inspiration of bionic structures from nature can lead to economical advantages in comparison to traditional manufacturing processes.

Serivce is a critical aspect to ensure the success of your additive manufacturing machines. The access to training, remote troubleshooting, service visits, consumables and spare parts keeps your production running smoothly.

SLM Solutions prides itself on being a full-service partner to our customers. Our team offers experienced field service engineers around the globe to ensure your system stays up and running at peak performance. Should something go wrong, our strategically located warehouses stock spare parts, many which are available to be shipped same-day. Choosing the right technology is critical, but forging partnerships with the optimal AM technology provider is the fastest path to success. Partner with SLM Solutions!

Sustainability and Additive Manufacturing

Did You Know? Innovative technologies like selective laser melting are not only able to provide economical benefits. There are some aspects that help to protect the environment. With SLM® technology natural resource usages is reduced through energy efficient machines and material consumption is minimized by processing metal powder only where the build geometry requires, thus reducing the scrap of traditional machining processes. See below.

Lightweight Design

The freedom of design that Selective Laser Melting provides enables internal cooling channels or structures, thus a stringent lightweight design of parts is possible. This helps to improve fuel efficiency, e.g. in the automotive sector

Waste Reduction

Selective Laser melting technology is not based on removeing material (subtractive technologies), it adds material where needed - leading to waste reduction.

On-Site Production

With local and on demand production of metal parts, shipments can be reduced, while minimizing storage costs.