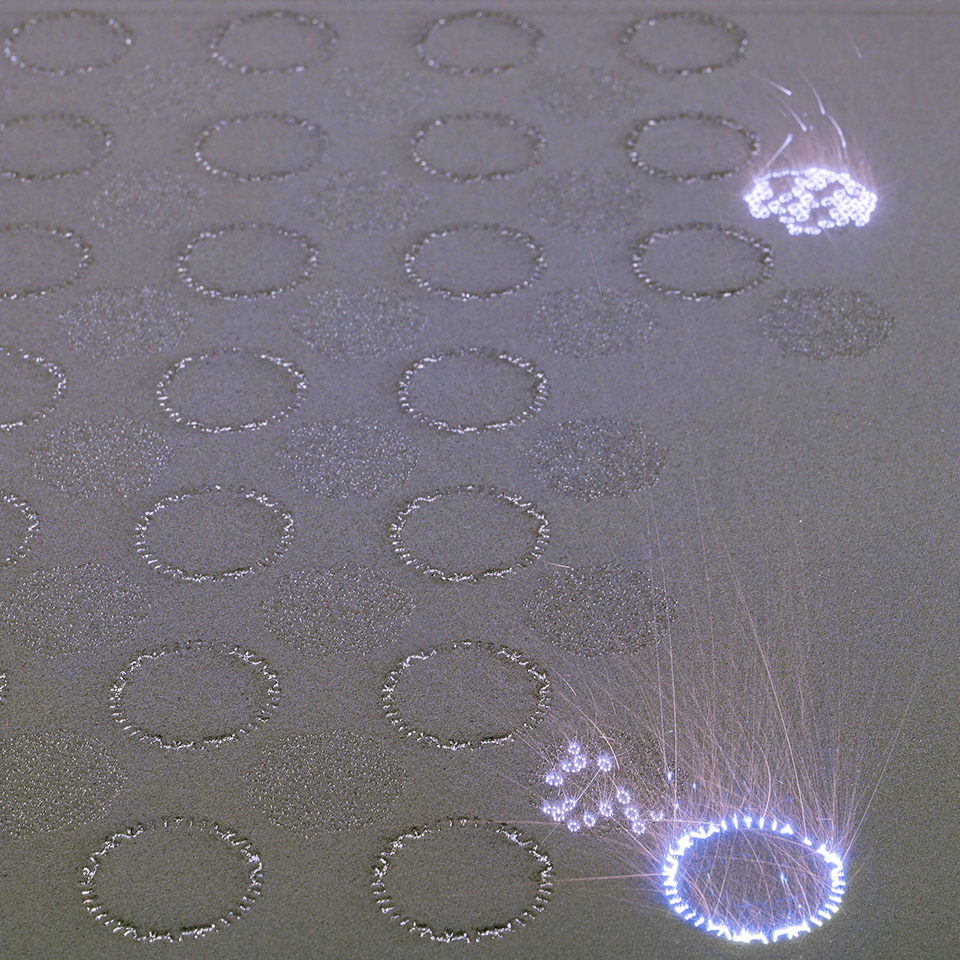

Selective Laser Melting machines from SLM Solutions feature multi-laser options, bi-directional recoating and closed-loop powder handling to achieve best-in-class safety and increased build speeds for complex and completely dense metal parts.

Ready for Industrialization and Series Production

Discover the right Selective Laser Melting System to suit your production process!

Our robust SLM® machines offer fast, reliable and cost-efficient part production. We work with you at each stage of the process to elevate use of the technology, ensure your return on investment is maximized and keep SLM® machines running at peak performance at your facility.

As the innovation leader in the selective laser melting field, SLM Solutions focuses on both productivity increases and material characteristics. SLM® machines offer efficient processing of reactive and non-reactive materials for high-quality build parts.

SLM Solutions helped invent the laser powder bed fusion process, was the first to offer multi-laser systems and all selective laser melting machines offer patented quality, safety and productivity features.

SLM Solutions machines are equipped with high-technology features that ensure a closed-loop powder handling an inert atmosphere to protect the operator from exposed powder.

Whether it is the material, the consistent quality of components or tools for quality assurance, SLM® machines are equipped with high-tech features that ensure high accuracy in every process step.

Increased productivity is crucial for production-oriented machines. SLM Solutions multi-laser machines are tailored to your needs to speed up your production.

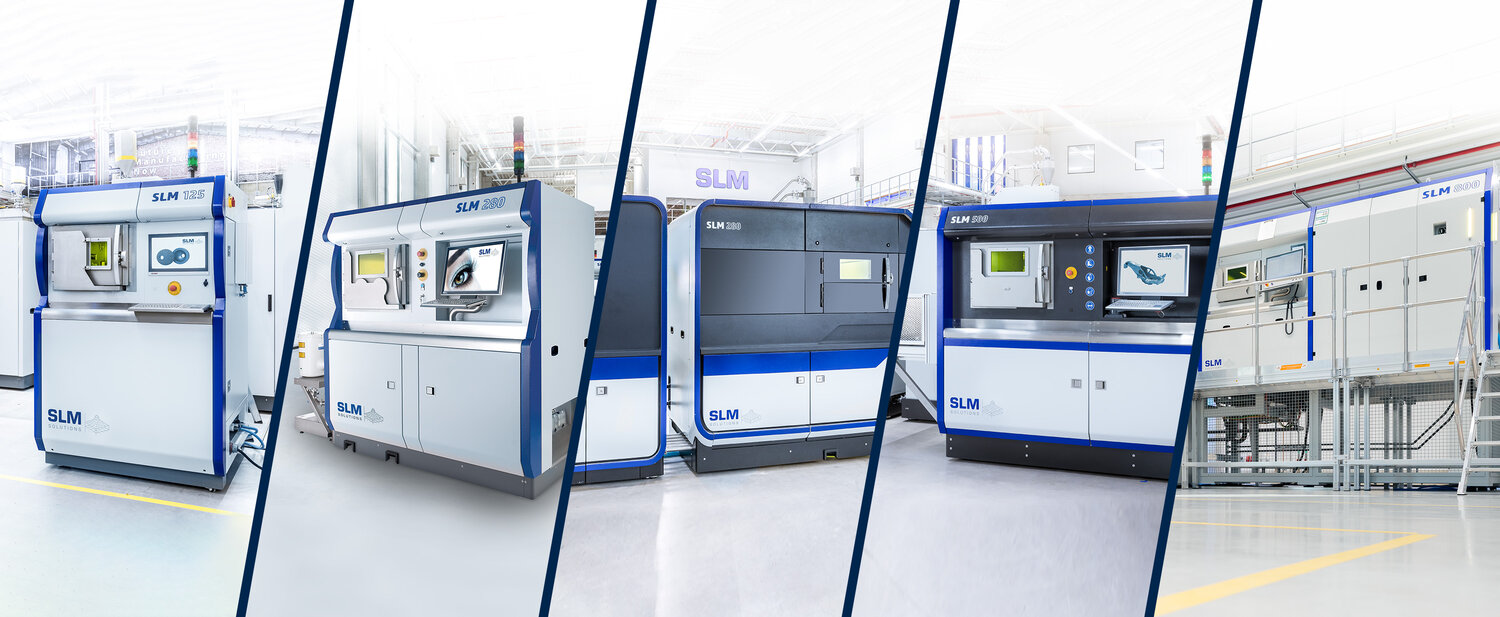

SLM®125

- High Power Laser in a Compact Footprint for Flexible Manufacturing

- Versatile Selective Laser Melting

- Build envelope of 125 x 125 x 125 mm or reduced to 50 x 50 x 50 mm with a single 400W fiber laser.

SLM®280 2.0

- Metal 3D printing with closed-loop powder handling

- Multiple Lasers with high productivity with Demanding Applications

- Up to 1400W based on 2 x 700 W laser technology

- 280 x 280 x 365 mm build envelope

SLM®280 Production Series

- Third-generation metal 3D printing with closed-loop powder handling

- Multiple Lasers with high productivity with Demanding Applications

- Up to 1400W based on 2 x 700 W laser technology

- 280 x 280 x 365 mm build envelope

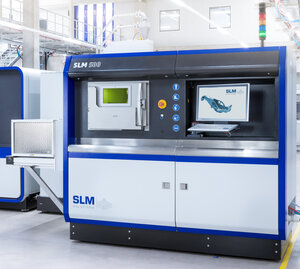

SLM®500

- The first quad-laser metal system on the market for high volume metal additive manufacturing

- Production ready, optimized for fast multi-laser, cost efficient builds for high volume projects

- Featuring a 500 x 280 x 365 mm build chamber and configurable with two or four overlapping lasers with power ratings from 800 to a full 2800 Watts, including part removal station, reduced machine downtime and increased productivity for low part costs

SLM®800

- First combined multi-machine setup with up to five machines for industrial production

- Large build envelope 500 x 280 x 850 mm (length x width x depth)

- Quad 700W technology ensure highest build efficiency

- Our HUB ensures fully automated cylinder handling and powder management

SLM®280 2.0

Metal 3D printing with multiple lasers and closed-loop powder handling. The SLM®280 2.0 is ideal for medium to high volume metal additive manufacturing part production and prototypes.

- 280 x 280 x 365 mm build envelope

- Multi-laser (twin)

- Multi-material

SLM®280 2.0

Metal 3D printing with multiple lasers and closed-loop powder handling. The SLM®280 2.0 is ideal for medium to high volume metal additive manufacturing part production and prototypes.

- 280 x 280 x 365 mm build envelope

- Multi-laser (twin)

- Multi-material

- Multi-material

- Multi-material

- Multi-material

SLM®280 2.0

Metal 3D printing with multiple lasers and closed-loop powder handling. The SLM®280 2.0 is ideal for medium to high volume metal additive manufacturing part production and prototypes.

- 280 x 280 x 365 mm build envelope

- Multi-laser (twin)

- Multi-material

SLM®280 2.0

Metal 3D printing with multiple lasers and closed-loop powder handling. The SLM®280 2.0 is ideal for medium to high volume metal additive manufacturing part production and prototypes.

- 280 x 280 x 365 mm build envelope

- Multi-laser (twin)

- Multi-material

- Multi-material

- Multi-material

- Multi-material

SLM®280 2.0

Metal 3D printing with multiple lasers and closed-loop powder handling. The SLM®280 2.0 is ideal for medium to high volume metal additive manufacturing part production and prototypes.

- 280 x 280 x 365 mm build envelope

- Multi-laser (twin)

- Multi-material

SLM®280 2.0

Metal 3D printing with multiple lasers and closed-loop powder handling. The SLM®280 2.0 is ideal for medium to high volume metal additive manufacturing part production and prototypes.

- 280 x 280 x 365 mm build envelope

- Multi-laser (twin)

- Multi-material

- Multi-material

- Multi-material

- Multi-material