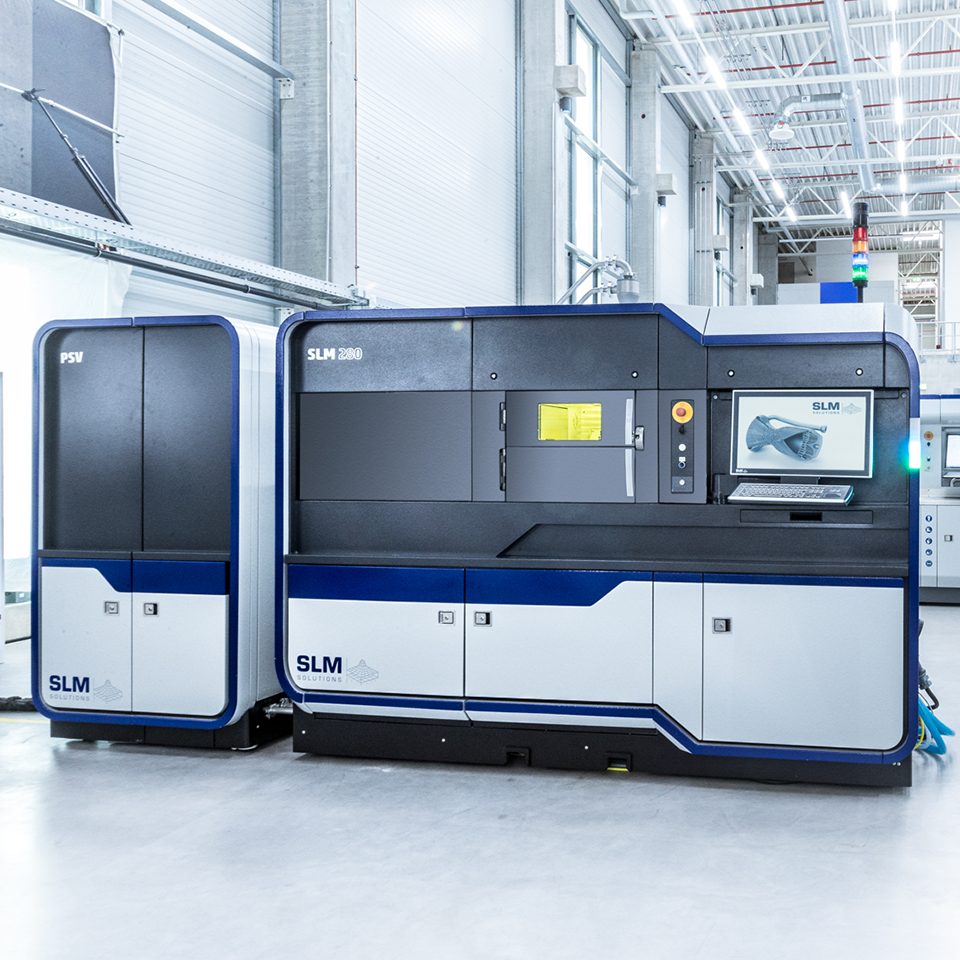

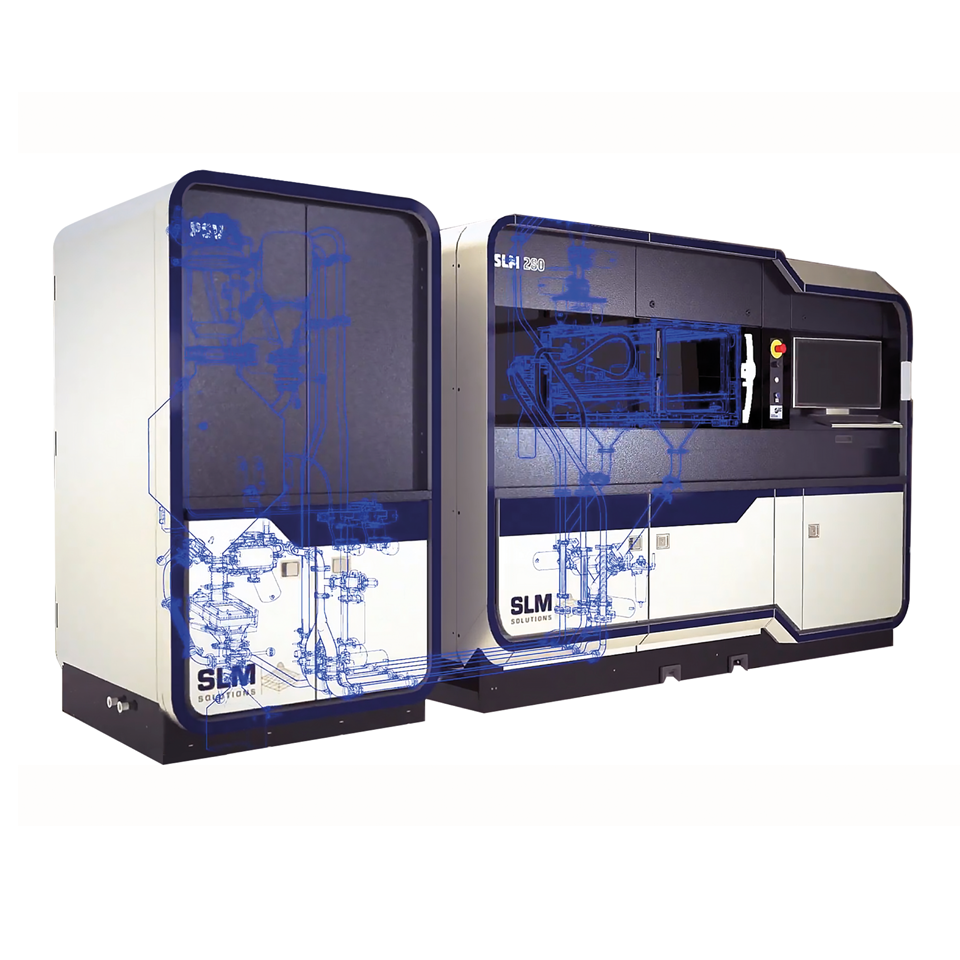

SLM®280 Production Series

- Third-generation metal 3D printing with closed-loop powder handling

- Multiple Lasers with high productivity with Demanding Applications

- Up to 1400W based on 2 x 700 W laser technology

- 280 x 280 x 365 mm build envelope

SLM®280 Production Series

With a build plate 25% larger than standard mid-sized machines to fit more parts per build, the SLM®280 Production Series is a high-power, multi-laser machine designed for production oriented additive manufacturing. The SLM®280 Production Series utilizes our patented multi-laser scan strategy to minimize soot interference, alter layer stitching and deliver results with the same density and mechanical properties as single-laser builds.

Gas Flow Ensures Highest Part Quality

The SLM®280 Production Series provides a patented, enhanced gas flow that creates a clean process environment and increase build quality over the total build job in x, y and in z axis up to the complete height. A permanent filter module additionally increases machine uptime and safety. Powder transport, sieving and storage is contained within an inert gas atmosphere to maintain material quality

Permanent Filter Module Improves Machine Uptime and Reduces Costs

The Permanent Filter Module traps process soot in a sintered plate filter and coats the waste material with an inhibitor for dry disposal. Machine uptime is increased, gas flow is stabilized and consumable costs are reduced, all while increasing safety.

Closed Loop Powder Handling Increases Safety and Material Quality

Powder transport, sieving and storage is contained within an inert gas atmosphere to maintain material quality

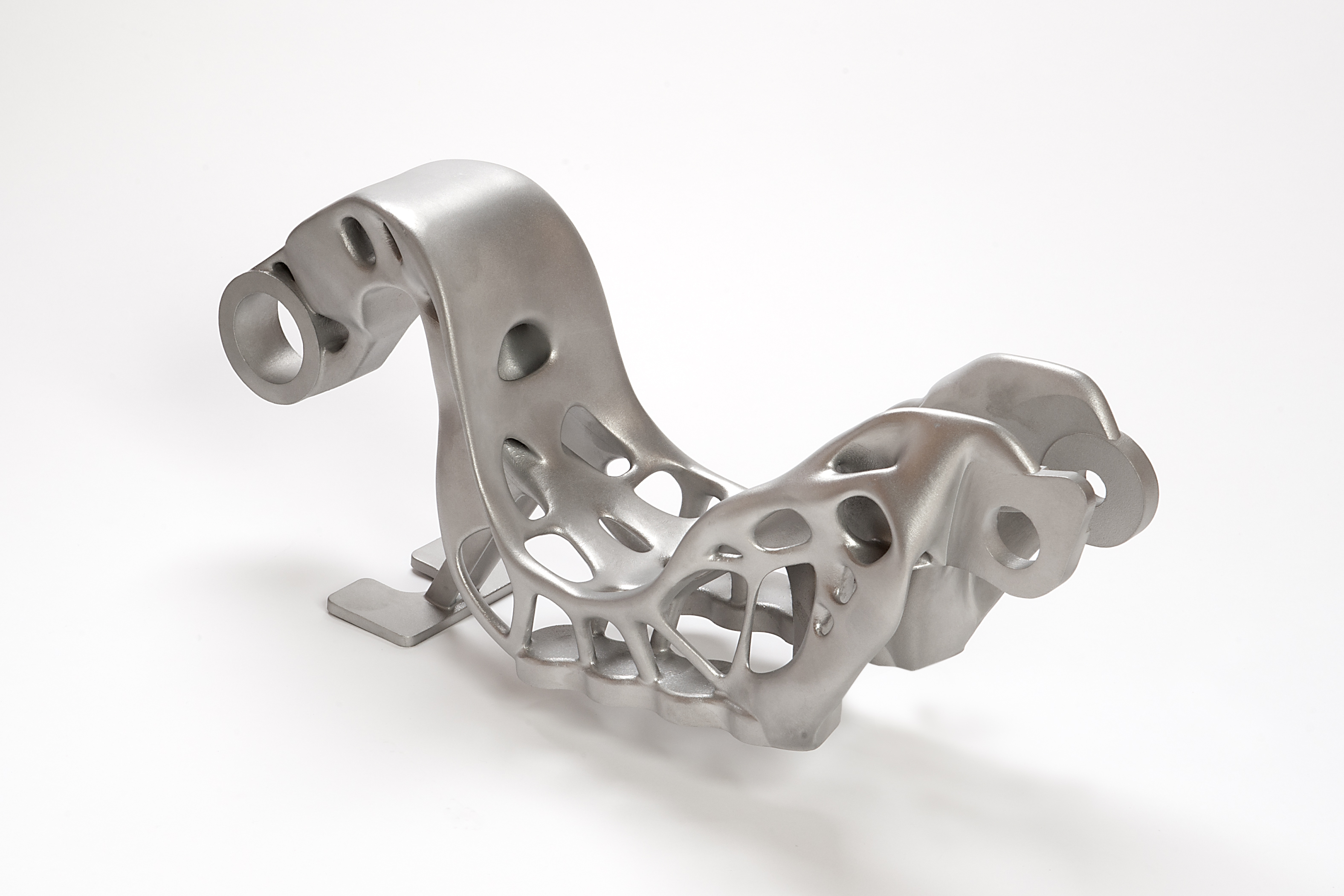

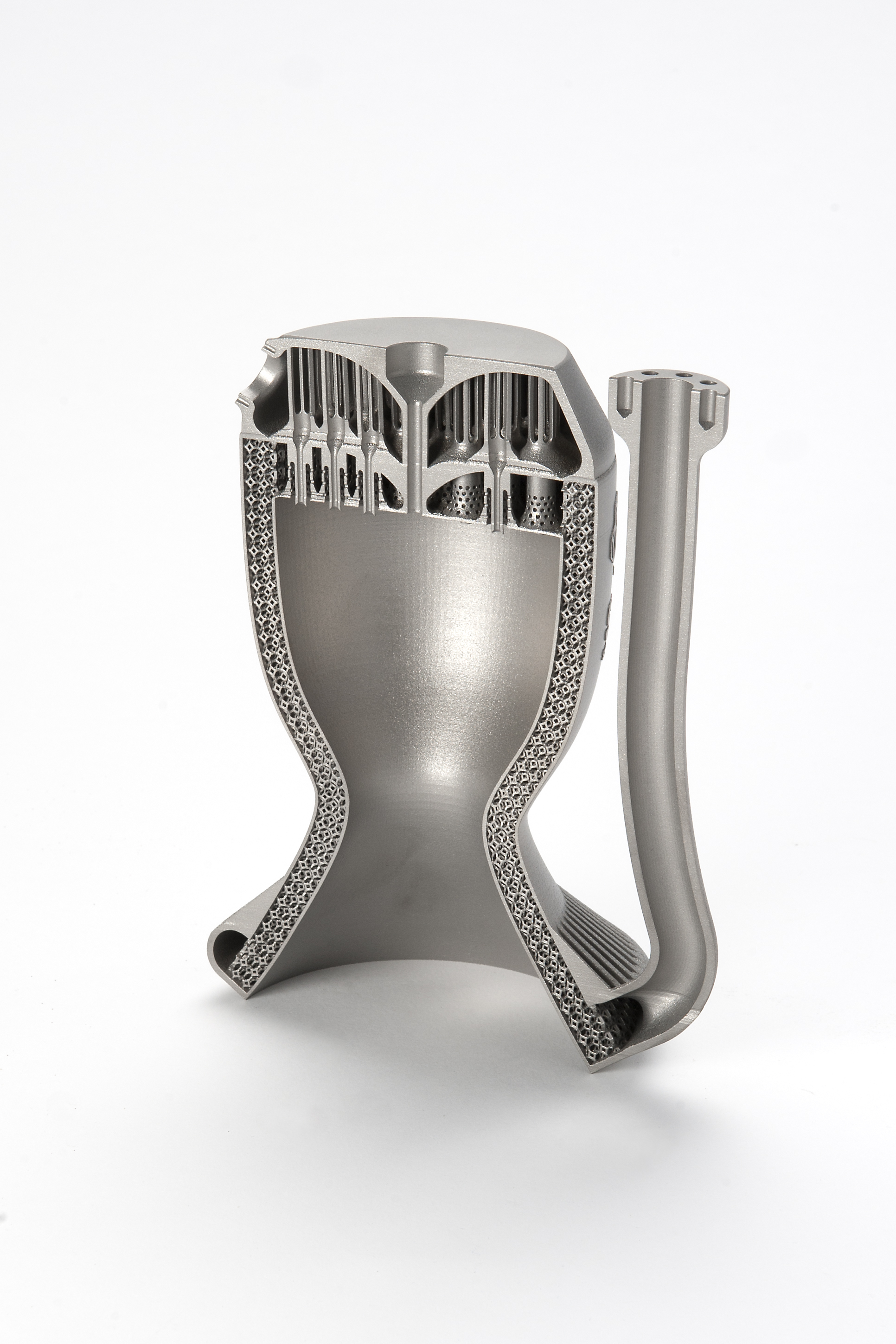

SLM®280 Production Series Real World Parts

SLM®280 Accessories

A byproduct of the welding process is submicronic soot and condensate, which can be pyrophoric by nature. The permanent filter module traps soot and condensate particles from the process gas stream in a sintered plate filter. The filter is purged with gas, the waste material coated with an inhibitor and dropped in a bin for dry disposal, while clean gas returns to the process chamber.

- Long-life filter ensures part quality throughout builds without interruption

- No changing of filter cartridges

- Reduced consumable costs

- Safer operation by avoiding loaded filter housing exchange

- Dry mixture waste disposal without hydrogen formation with reactive materials

Melt Pool Monitoring (MPM) is an available on-axis tool for visualizing the melt pool in the SLM® process. Data from MPM can be used as a resource for efficiently developing and evaluating the process parameters. In the production of safety-critical parts, the data collected serves as documentation for quality assurance.

Laser Power Monitoring (LPM) is an available on-axis monitoring system that continuously measures and documents target and actual emitted laser output throughout the production process.

Developed to simplify cleaning, maintenance and installation work on the SLM®Recoater.

- Stable mount for maintenance

- Safe handling

- Station features 360° rotation for full maintenance access

- Drip tray included for easy residual powder collection

- Safe storage of recoating mechanisms

- Station Dimensions: 730mm x 310mm x 250mm

Tool to level recoater height and adjust overlap area. Enables reproducible adjustments to the recoating lip height, independent from operator, within 1 μm. Resulting in recoating and the laser exposure level consistency for each build job

Substrate plates with parts up to 180kg can be easily removed from the process chamber with the Build Plate Handling Device.

- Two-speed electronic lifting and lowering

SLM®280 Technical Specifications

Build Envelope (L x W x H): | 280 x 280 x 365 mm |

Build Volume Reduction (L x W x H): | 50 x 50 x 50 mm |

3D Optics Configuration: | Single (1x 400 W or 1x 700 W) IPG fiber laser Twin (2x 400 W or 2x 700 W) IPG fiber laser Dual (1x 700 W and 1x 1000 W) IPG fiber laser |

Build Rate: | up to 113 cm³/h (Twin 700 W) |

Variable Layer Thickness: | 20 µm - 90 µm (more upon request) |

Minimum Feature Size: | 150 µm |

Beam Focus Diameter: | 80 µm - 115 µm |

Maximum Scan Speed: | 10 m/s |

Average Inert Gas Consumption in Process: | 13 l/min (argon) |

Average Inert Gas Consumption Purging: | 160 l/min (argon) |

E-Connection / Power Input: | 400 Volt 3NPE, 63 A, 50/60 Hz, 3.5-5.5 kW |

Compressed Air Requirement / Consumption: | ISO 8573-1:2010 [1:4:1], 60 l/min @ 6 bar |

Dimensions (L x W x H): | 4150 mm x 1200 mm x 2525 mm (includes PSV) |

Weight: | 1700 kg dry |