SLM®280 2.0

- Metal 3D printing with closed-loop powder handling

- Multiple Lasers with high productivity with Demanding Applications

- Up to 1400W based on 2 x 700 W laser technology

- 280 x 280 x 365 mm build envelope

SLM®280 2.0

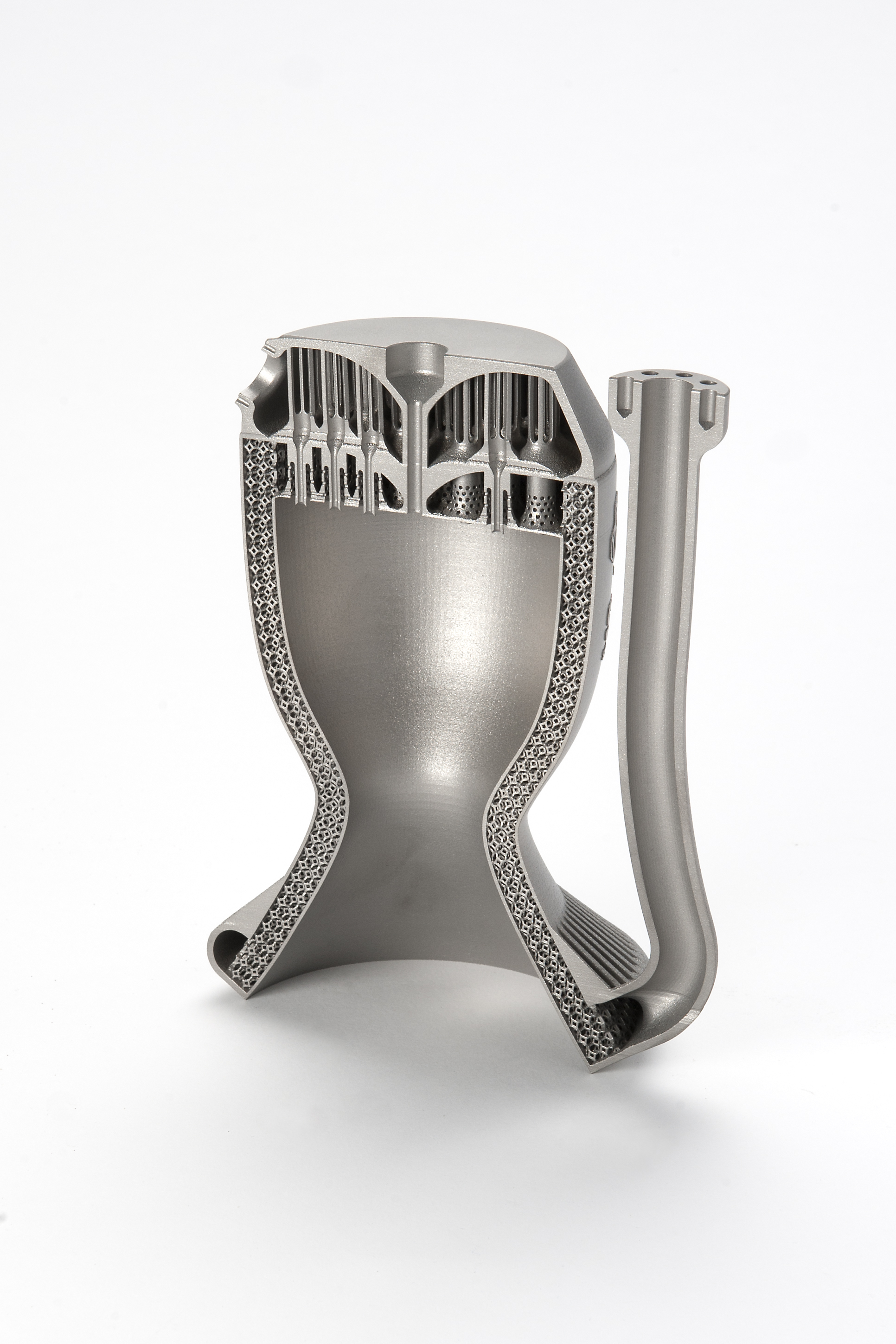

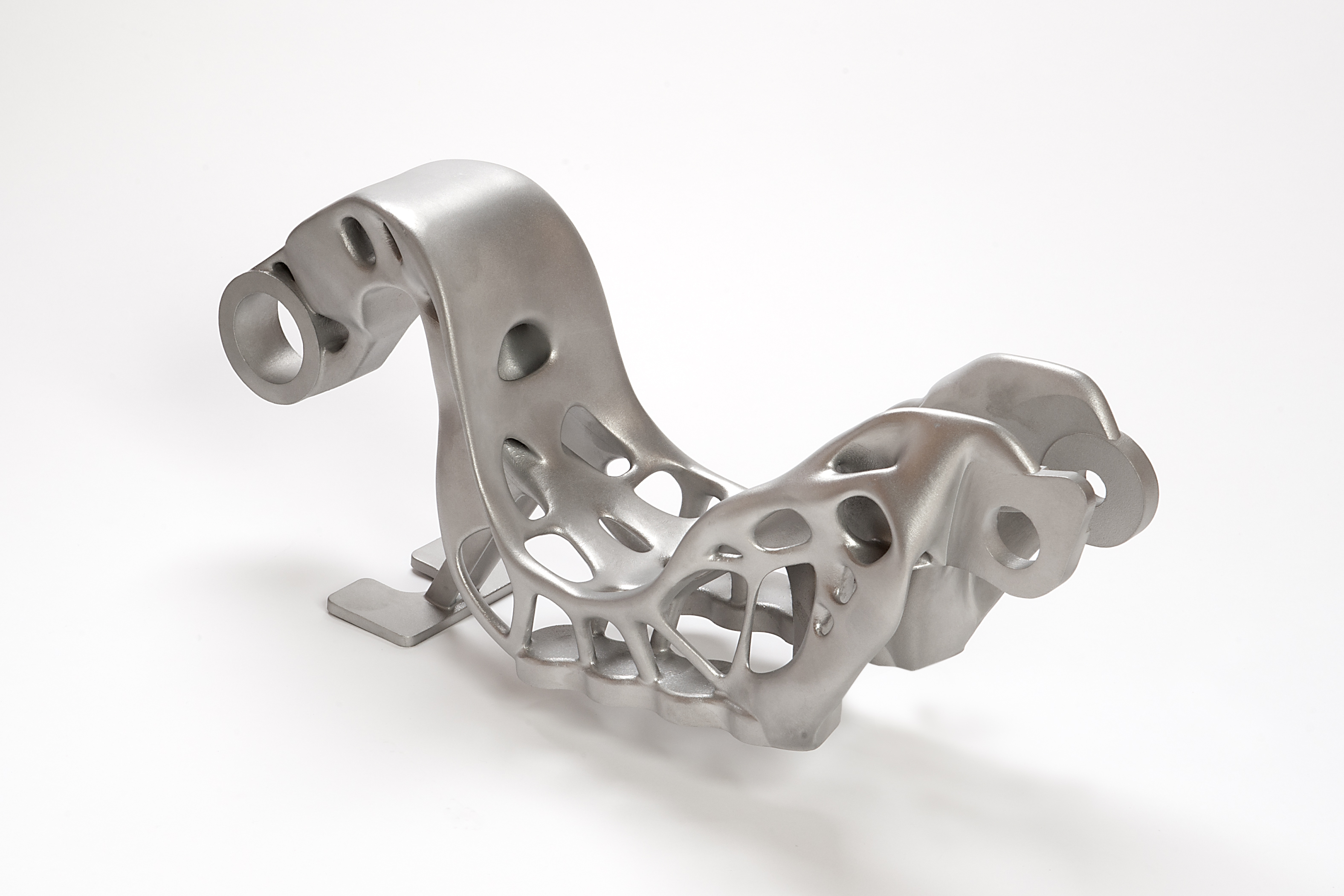

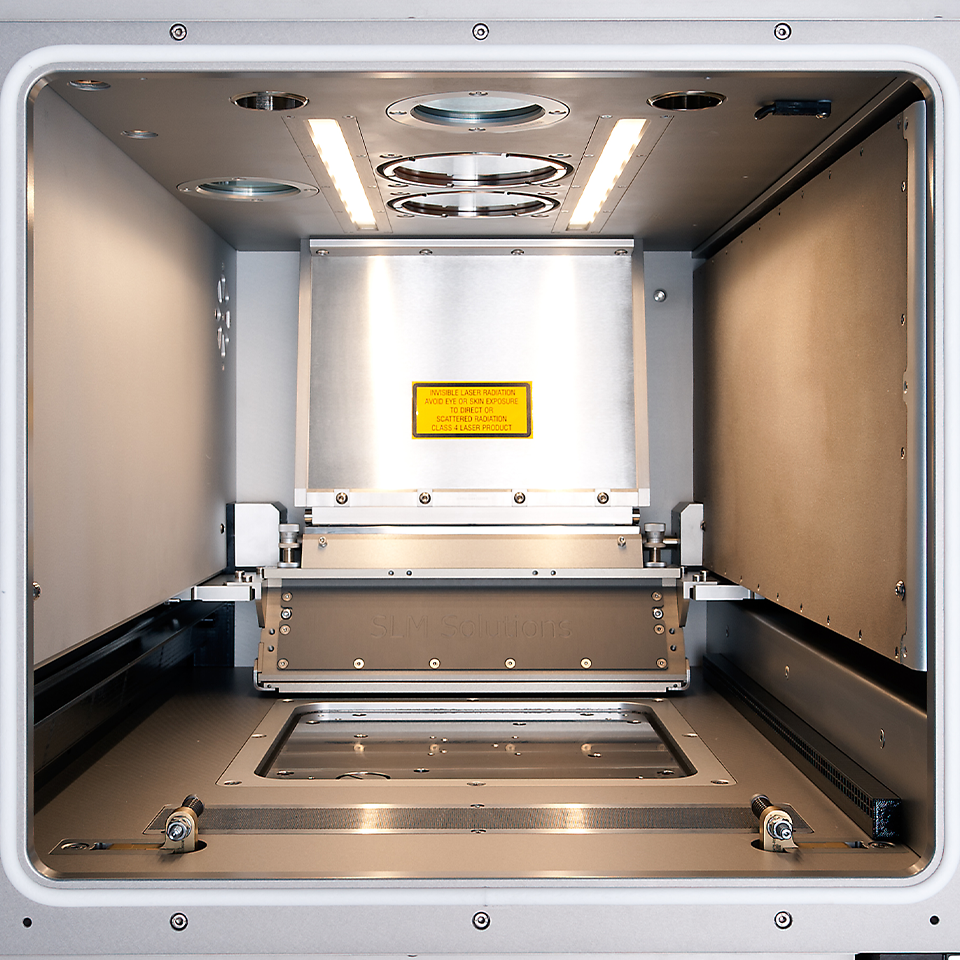

Ideal for medium to high volume metal part production and prototypes, the robust second generation SLM®280 2.0 selective laser melting system offers a 280 x 280 x 365 mm build envelope and patented multi-beam laser technology with up to two fiber lasers exposing the build field via a 3D scan optic. Multi-laser systems can achieve build rates 80% faster than a single laser, and patented bi-directional powder recoating minimizes manufacturing time by reducing the number of passes required to lay fresh powder during a build.

Outfitted with a standard PSM powder sieve, overflow bottles transfer material between sieve and machine reducing operator contact with loose powder. PSM sieves and powder change kits allow users material flexibility while maintaining powder quality in an inert atmosphere.

Multi-laser Technology

The SLM®280 can be equipped with up to two 700W fiber lasers to accelerate the printing process of many metal additive powders.

Highest Productivity

Patented bi-directional powder recoating helps reduce manufacturing time by depositing a new layer of powder in both directions without having to return to a “home” position.

Material Flexibility

Paired with a Powder Sieving Machine (PSM), the SLM®280 offers material flexibility. Manual sieves allow efficient material changeover for adaptable production while maintaining safety and quality

SLM®280 Real World Parts

SLM®280 Accessories

The PSM unit sieves and separates metal powder under inert gas conditions. Metal powder collected from overflow cans in the selective laser melting system is manually supplied to the sieving station. The sieved GO grain and oversized powder are collected in separate cans underneath the system for further use.

The sieving process runs automatically without influence on the running build process, reducing ancillary times. To support and speed up the sieving procedure, an additional ultrasonic cleaning device can be added.

Melt Pool Monitoring (MPM)

Tool for visualizing thermal emission of melt pool in the SLM®process. The system records the thermal radiation produced from the melt during the entire production process

- Sequential output of thermal emission plot images of individual layers

- Detect irregularities and defects in parts

- Log and document build jobs in MPM-Files

Laser Power Monitoring (LPM)

Permanent on-axis laser power monitoring system that measures and illustrates nominal and actual power during the ongoing manufacturing process.

- Active warnings, highlighting spots with critical laser power deviation

- Documentation of the laser power for each scan vector over the entire build job

Developed to simplify cleaning, maintenance and installation work on the SLM®Recoater.

- Stable mount for maintenance

- Safe handling

- Station features 360° rotation for full maintenance access

- Drip tray included for easy residual powder collection

- Safe storage of recoating mechanisms

- Station Dimensions: 730mm x 310mm x 250mm

Tool to level recoater height and adjust overlap area. Enables reproducible adjustments to the recoating lip height, independent from operator, within 1 μm. Resulting in recoating and the laser exposure level consistency for each build job

Substrate plates with parts up to 180kg can be easily removed from the process chamber with the Build Plate Handling Device.

- Two-speed electronic lifting and lowering

SLM®280 Technical Specifications

Build Envelope (L x W x H): | 280 x 280 x 365 mm |

3D Optics Configuration: | Single (1x 400 W or 1x 700 W) IPG fiber laser Twin (2x 400 W or 2x 700 W) IPG fiber laser |

Build Rate: | 88 cm³/h (400 W Twin) |

Variable Layer Thickness: | 20 µm - 75 µm |

Minimum Feature Size: | 150 µm |

Beam Focus Diameter: | 80 µm - 115 µm |

Maximum Scan Speed: | 10 m/s |

Average Inert Gas Consumption in Process: | 2.5 l/min (argon) |

Average Inert Gas Consumption Purging: | 70 l/min (argon) |

E-Connection / Power Input: | 400 Volt 3NPE, 63 A, 50/60 Hz, 3.5-5.5 kW |

Compressed Air Requirement / Consumption: | ISO 8573-1:2010 [1:4:1], 50 l/min @ 6 bar |

Dimensions (L x W x H): | 2600 mm x 1200 mm x 2760 mm |

Weight: | 1300 kg dry |