SLM®800

- First combined multi-machine setup with up to five machines for industrial production

- Large build envelope 500 x 280 x 850 mm (length x width x depth)

- Quad 700W technology ensure highest build efficiency

- Our HUB ensures fully automated cylinder handling and powder management

SLM®800

The SLM®800 efficiently builds large components and opens new production possibilities. All SLM Solutions’ patented innovations have been scaled up and partnered with features such as a metal recoating brush, permanent filter module and centralized powder supply to enable successful large builds.

The SLM®HUB and optional Build Cylinder Magazine create an automated, multi-machine production manufacturing cell. The result: A fully automated handling station which maximizes machine uptime and offers a no-contact powder solution for production processes.

Ready for Serial Production

The SLM®800 utilizes the proven quad-laser technology with four times 700 W laser power of the SLM®500 with an extended z-axis for larger production builds. Vertically extending the build envelope reduces exposure per layer. Higher part quality, in particular for flatness and reduced internal material stress, for long components realized due to vertical build job. Decreased supports through vertical orientation also reduces material usage and post-processing.

Improved Machine Uptime and Reduces Costs

The permanent filter module traps process soot in a sintered plate filter that is purged with safety gas. The waste material is coated with an inhibitor and stored in a bin for dry disposal, while clean gas returns to the process chamber, stabilizing gas flow to ensure part quality throughout long builds without interruption. The elimination of consumable filter cartridges increases safety while improving machine uptime and reducing costs.

Fully Automatic Powder Handling

Each SLM®800 features an integrated powder tank to supply the machine with a direct source of material. The additional central powder supply unit (CPS) features two 220l tanks, one fixed for delivery to the machine and one portable for powder refill. Sieves are located both in between the two CPS tanks and on the machine directly before use to ensure powder quality throughout the process. This leads to an increased machine uptime, high safety and material quality.

Fully Automated Build Cylinder Handling

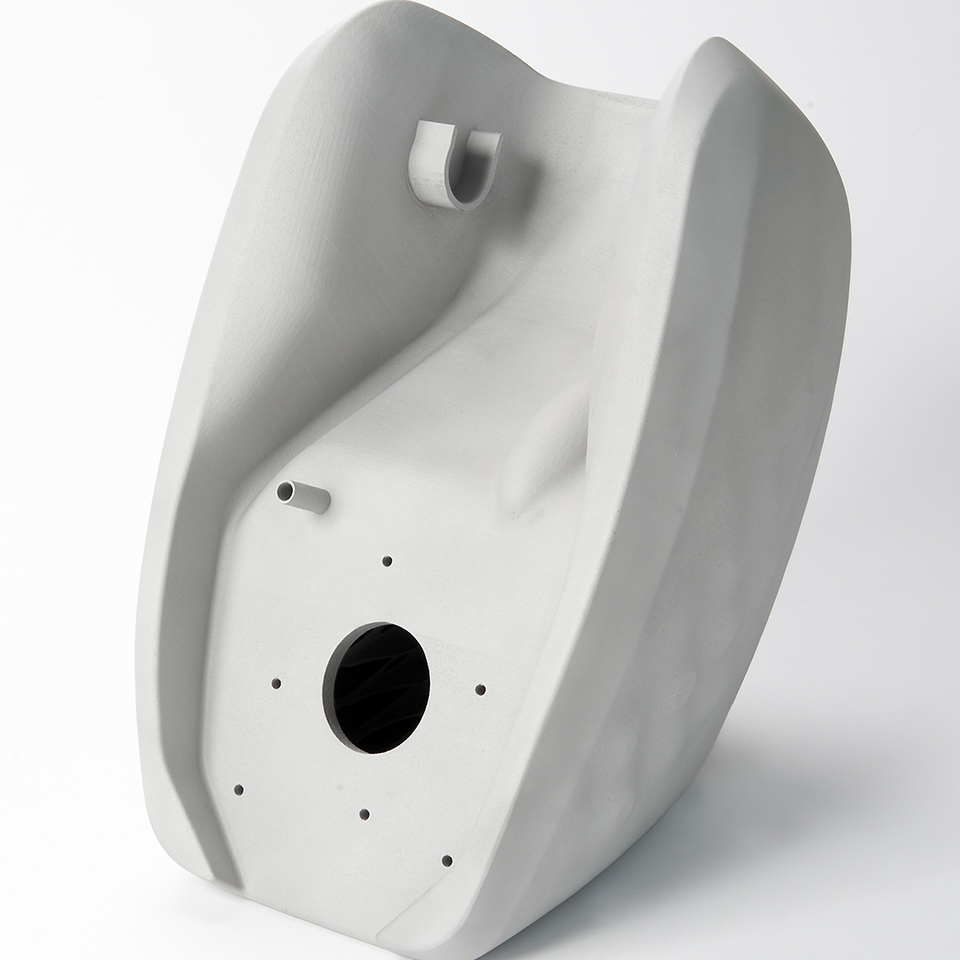

The SLM®HUB utilizes a linear axis to drive build cylinders internally between four integrated stations and directly into or out of the SLM®800 machine.

Those four stations allows an automated de-packing of the part out of the cylinder by pulling up the cylinder first, followed by turning and vibrating the part to ensure highest powder free cleanness level. All this under inert conditions in order to keep highest powder quality. All powder will be recovered and returned to one of the five attached SLM®800 machines. The handling position gives the possibility to remove powder free parts and to insert blank substrate plates into the HUB, which are combined with the cylinder on the merge station. The heating up, as well as the cooling down of the cylinders happens on the parking station.

Patented Gas Flow

SLM Solutions patented turbulent-free gas flow stream ensure a maximum efficient remove of condensate in the build chamber. The resulting constant high laser power, which reaches the powder bed, allows best part quality over the total height of the build job.

SLM®800 Real World Parts

SLM®800 Accessories

SLM®HUB

The SLM®800 reaches peak performance when paired with the SLM®HUB fully-automated handling station. This integrated solution features automated transport of build cylinders with dedicated locations for pre-heating and cooling in an inert atmosphere. The SLM®HUB also removes manual powder handling from the production process with a centralized powder supply and a powder removal chamber that rotates and vibrates the finished substrate plate to automatically separate unused powder from the finished part and recycle it back to the sieving station for reuse in future builds. All machines connected to the SLM®HUB are fed metal powder through vacuum technology from the central powder station creating a completely closed-loop powder management system under while ensuring an inert gas atmosphere.

Up to five SLM®800 systems can be modularly connected to and operated from a single SLM®HUB. With a build cylinder magazine (BCM) multiple build cylinders can be handled in parallel to optimize machine uptime and scale to full production

Provides a consistent powder bed over thousands of layers and beneficial for efficient job changeover. Brush durability ensures stable recoating while enabling error correction during the build.

- Haynes 25 or IN718, tested and approved for use with any material

- Testing shows brush stability at over 100,000 layers

- In the event of a collision with an extrusion up to 3mm from the powder bed, the bristles bend and do not break.

- Allows for correction of a build defect without damage to either recoater or part

Developed to simplify cleaning, maintenance and installation work on the SLM®Recoater.

- Stable mount for maintenance

- Safe handling

- Station features 360° rotation for full maintenance access

- Drip tray included for easy residual powder collection

- Safe storage of recoating mechanisms

- Station Dimensions: 730mm x 310mm x 250mm

Melt Pool Monitoring (MPM)

Tool for visualizing thermal emission of melt pool in the SLM®process. The system records the thermal radiation produced from the melt during the entire production process.

- Sequential output of thermal emission plot images of individual layers

- Detect irregularities and defects in parts

- Log and document build jobs in MPM-Files

Laser Power Monitoring (LPM)

Permanent on-axis laser power monitoring system that measures and illustrates nominal and actual power during the ongoing manufacturing process.

- Active warnings, highlighting spots with critical laser power deviation

- Documentation of the laser power for each scan vector over the entire build job

Tool to level recoater height and adjust overlap area. Enables reproducible adjustments to the recoating lip height, independent from operator, within 1 μm. Resulting in recoating and the laser exposure level consistency for each build job.

SLM®800 Technical Specifications

Build Envelope (L x W x H): | 500 x 280 x 850 mm |

3D Optics Configuration: | Quad (4x 700 W) IPG fiber laser |

Build Rate: | up to 171 cm³/h (Quad 700 W) |

Variable Layer Thickness: | 20 µm - 90 µm |

Minimum Feature Size: | 150 µm |

Beam Focus Diameter: | 80 µm - 115 µm |

Maximum Scan Speed: | 10 m/s |

Average Inert Gas Consumption in Process: | 5-7 l/min (argon) |

Average Inert Gas Consumption Purging: | 70 l/min (argon) |

E-Connection / Power Input: | 400 Volt 3NPE, 63 A, 50/60 Hz, 8-10 kW |

Compressed Air Requirement / Consumption: | ISO 8573-1:2010 [1:4:1], 50 l/min @ 6 bar |

Dimensions (L x W x H): | Dependant on steup |

Weight: | Dependant on setup |