Materials

Powder

SLM Solutions offers qualified metal powder & material parameters

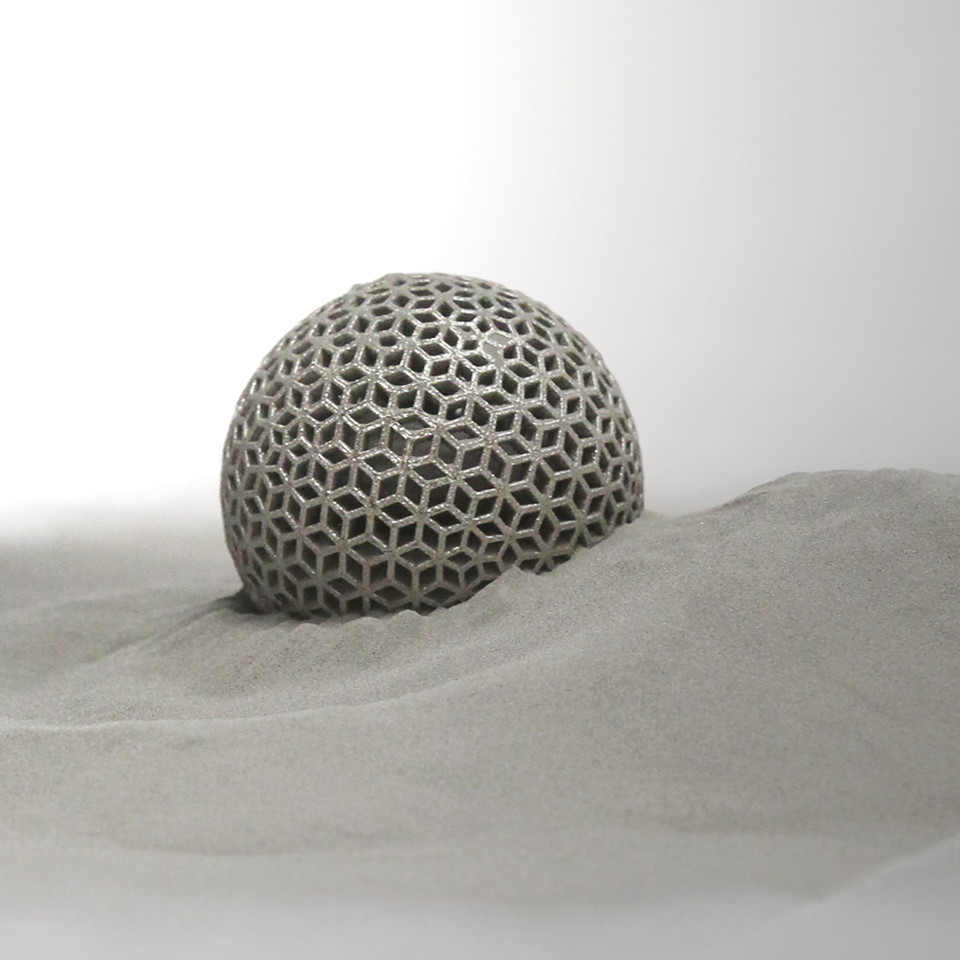

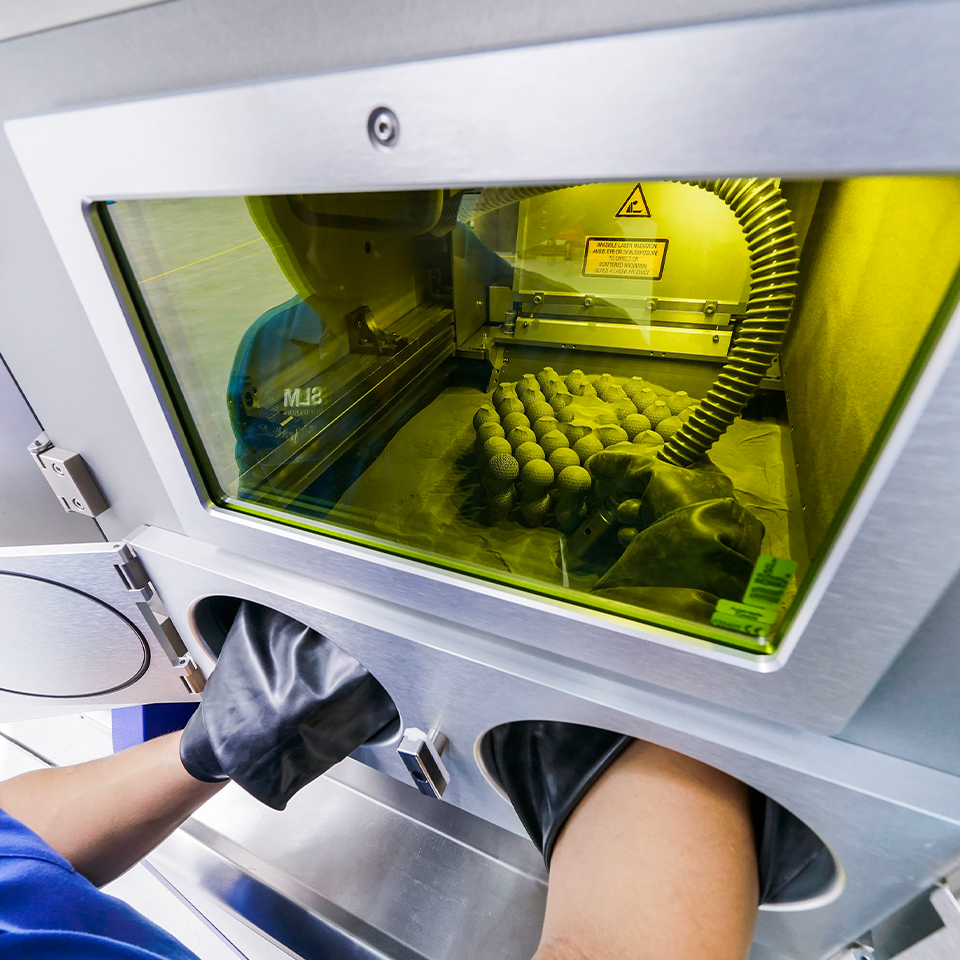

The raw of the selective laser melting process is spherical metal powder, usually in a nominal particle size distribution of 10 – 45 or 20 - 63 µm micrometer. SLM Solutions provides a range of highly qualified metal powders and unique parameter sets to guarantee SLM® machines are running at peak performance. Because the properties of the metal powder utilized by SLM® machines affect the achievable results, SLM Solutions has established a powder division in 2016 to supply customers with materials that ideally fit selective laser melting machines for qualified serial production. Our open architecture systems are thereby open for your individual adjustments and developments.

Powder Selection

High-quality part production using metal AM requires critical performance criteria for metal powder to be well defined and stringently applied to the supply chain. SLM Solutions operates a structured powder quality assurance process, governed by ongoing supply-chain agreements that ensure the high-level standards are maintained. In order to guarantee compliance to our specifications, our own quality inspection additionally checks every internally and externally used metal powder batch according to our high standards. There is a guarantee for feasibility on SLM® machines.

Parameter Development

We provide precisely engineered parameters matching every offered material for SLM® machines, which enables additive manufacturing of high-quality components designated for technical applications. Whether you are seeking for individual parameter adaptions or generic parameters for SLM® powders, we help you to find your way through the variety of possibilities, ensuring highest productivity and your success with additive manufacturing. Find the qualified test results published in our material data sheets.

Handling and Standards

When working with metal powders and depending on the territory where you are operating, there is a range of standards around staff care, handling and storage of materials, housekeeping requirements, audits and documentation. All companies operating AM systems should carry out risk assessments and develop an understanding of the regulatory framework and their health and safety obligations. At SLM Solutions, we have decades of experience in metal AM and have developed a deep understanding of the risks of metal powders and the laser powder bed fusion process (LPBF). We have designed our systems to overcome these risks and protect users and operating companies.

Metal powders available for nearly any of your Selective Laser Melting Process

"SLM Solutions has provided an excellent support to the University of Birmingham in customizing a research-based platform in order to work on exciting material and component challenges. Technical support and the upgrades we have received have been extremely beneficial in pushing forward the technology.”

University of Birmingham, Prof. Moataz Attallah, Director of AMPLab

Al-Based Alloys

SLM Solutions' AlSi10Mg is an aluminum-based alloy that is widely used in the additive manufacturing industry for production of functional parts as well as prototypes. AlSi10Mg is often used in applications requiring good mechanical properties and low weight.

Material characteristics

- Very good corrosion resistance

- Good electrical conductivity

- High dynamic toughness

- Excellent thermal conductivity

Typical application areas

- Aerospace

- Automotive

- Engineering

- Heat exchangers

Ni-Based Alloys

SLM Solutions' IN625 is a precipitation-hardenable nickel-based material alloyed with chromium, molybdenum, and niobium. IN625 is a typical material for construction of aircraft engine components with service temperatures below 650 °C.

Material characteristics

- High strength

- Good ductility

- Excellent creep rupture strength below 700 °C

- Excellent corrosion resistance

Typical application areas

- Aerospace

- Energy

- Chemical industry

- Turbine parts

SLM Solutions' IN718 is a precipitation-hardenable nickel-chromium-alloy. With excellent tensile, fatigue, creep, and rupture strengths up to 700 °C, IN718 is an important alloy for production of components for aircraft engines, (gas) turbines, and other high temperature applications.

Material characteristics

- High strength

- Good ductility

- Excellent mechanical properties up to 700 °C

- Excellent oxidation resistance

Typical application areas

- Aerospace

- Energy

- Chemical industry

- Turbine parts

Fe-Based Alloys

SLM Solutions' stainless steel 316L is an austenitic high chromium steel with excellent processability on SLM Solutions' additive manufacturing machines. 316L is often used in applications requiring good mechanical properties and excellent corrosion resistance, especially in chloride environments.

Material characteristics

- Very good corrosion resistance

- High strength under elevated temperatures

- High ductility

Typical application areas

- Aerospace / Automotive

- Surgical instruments

- Food industry

- Offshore installations

SLM Solutions' 15-5PH is a martensitic precipitation-hardening stainless steel that has excellent processability on SLM Solutions' additive manufacturing machines. 15-5PH is suitable for applications requiring high strength and hardness combined with moderate corrosion resistance. The alloy is the ferrite-free version of 17-4PH.

Material characteristics

- Precipitation-hardenable

- Excellent tensile strength

- Moderate corrosion resistance

Typical application areas

- Aerospace

- Medical

- Chemical / Petrochemical

- Paper / Metalworking industries

SLM Solutions' 17-4PH is a martensitic precipitation-hardening stainless steel. 17-4PH is suitable for applications requiring high strength and hardness combined with moderate corrosion resistance.

Material characteristics

- Precipitation-hardenable

- Excellent tensile strength

- Moderate corrosion resistance

Typical application areas

- Aerospace

- Medical

- Chemical / Petrochemical

- Paper / Metalworking industries

SLM Solutions' 1.2709 is a maraging tool steel with a high content of alloyed nickel and some molybdenum. 1.2709 is suitable for many tooling and high performance applications that require both high strength and toughness.

Material characteristics

- Martensitic hardening

- High toughness

- High tensile strength

- Good properties up to ca. 400 °C

Typical application areas

- Injection moulding

- Engineering parts

- Automotive

- Aerospace

SLM Solutions' H13 (1.2344) is a chromium containing martensitic tool steel. This material is used in tooling applications that require exceptional strength and toughness.

Material characteristics

- High tensile strength

- Moderate corrosion resistance

- Resistant to thermal fatigue cracking

Typical application areas

- Injection moulding

- Tooling

SLM Solutions' Fe-alloy Invar 36® is a high nickel containing steel that has a uniquely low coefficient of thermal expansion below its Curie temperature of 280 °C. Invar 36® is used in components that require a high dimensional stability over a wide range of temperatures.

Material characteristics

- Low coefficient of thermal expansion below its Curie temperature of 280 °C

- Excellent mechanical properties at cryogenic temperatures

- Low tendency to fatigue at low temperatures

Typical application areas

- Aerospace

- Valves in engines

- Precision instruments

Ti-Based Alloys

SLM Solutions' titanium alloy TiAl6V4 ELI (Grade 23) is the high purity version of TiAl6V4 (Grade 5), the most widely used titanium-based alloy in the world. Due to its high strength, low density, and good corrosion resistance, TiAl6V4 is highly suited for production parts in the aerospace and automotive industries as well as in biomedical applications.

Material characteristics

- Good corrosion resistance

- High specific strength

- High cycle fatigue strength

- High toughness

Typical application areas

- Aerospace

- Automotive

- Medical

- Energy

TA15 is a near-alpha titanium-alloy with additives of aluminum and zirconium. The high specific strength of components made of TA15 combined with their high load-bearing capacity and temperature resistance enable them to be used for heavy-duty components in aircraft and engine construction.

Material Characteristics

- Very good mechanical properties also in the high-temperature range

- High loadability even in multiaxial stress states

- High specific strength

- Good weldability

Typical application areas

- Aerospace

- Engine construction

SLM Solutions' Ti (Grade 2) is a commercially pure titanium grade with excellent biocompatibility and good mechanical properties. Ti (Grade 2) is widely used in many different applications that require excellent corrosion resistance, strength, ductility, and low density.

Material characteristics

- Excellent biocompatibility

- Excellent corrosion resistance to sea water

- Good ductility

- Moderate strength

Typical application areas

- Medical

- Aerospace

- Energy

- Chemical / Petrochemical

- Heat exchanger

Co-Based Alloys

SLM Solutions' CoCr28Mo6 is a cobalt, chromium, and molybdenum alloy with versatile applications. Owing to its exceptional biocompatibility, CoCr28Mo6 is used in the medical industry for the production of implants and prostheses. The material is also used to produce components for application in high temperature environments such as jet-engines.

Material characteristics

- Exceptional biocompatibility

- Heat resistant

- Resistance to thermal fatigue

- Oxidation resistance

Typical application areas

- Medical

- Aerospace

- Energy

- Turbine parts

SLM Solutions' SLM MediDent is a cobalt, chromium, molybdenum, and tungsten alloy especially designed for application in the dental industry. SLM MediDent is used primarily for the production of biocompatible dental implants and prostheses.

Material characteristics

- Biocompatible

- Corrosion resistant

Typical application areas

- Dental

- Medical

Cu-Based Alloys

The low-alloyed copper-alloy CuNi2SiCr is a thermally hardenable alloy with a high stiffness, even at elevated temperatures. Due to the low additives, the properties of pure copper (e.g. strength, softening temperature) can be considerably improved, while other properties (e.g. electrical conductivity, thermal conductivity, corrosion resistance) are largely retained. Typical areas of application are, for example, toolmaking, conductive contacts in electrical engineering or valves.

Material characteristics

- Balanced combination of electrical and thermal conductivity

- High wear resistance

- High corrosion resistance, in particular to stress corrosion cracking

Typical application areas

- Welding technology

- Electrical engineering

- Tool construction

DATA FOLLOWS