Services

We Support you at Each Step of Your Additive Manufacturing Journey!

To make your purchase decision easier, we offer various services, like benchmark production, job shop solutions or trainings. After your purchase our team of experienced field service engineers around the world ensure that your system stays up and running at peak performance.

Part Production

1. Benchmark Production

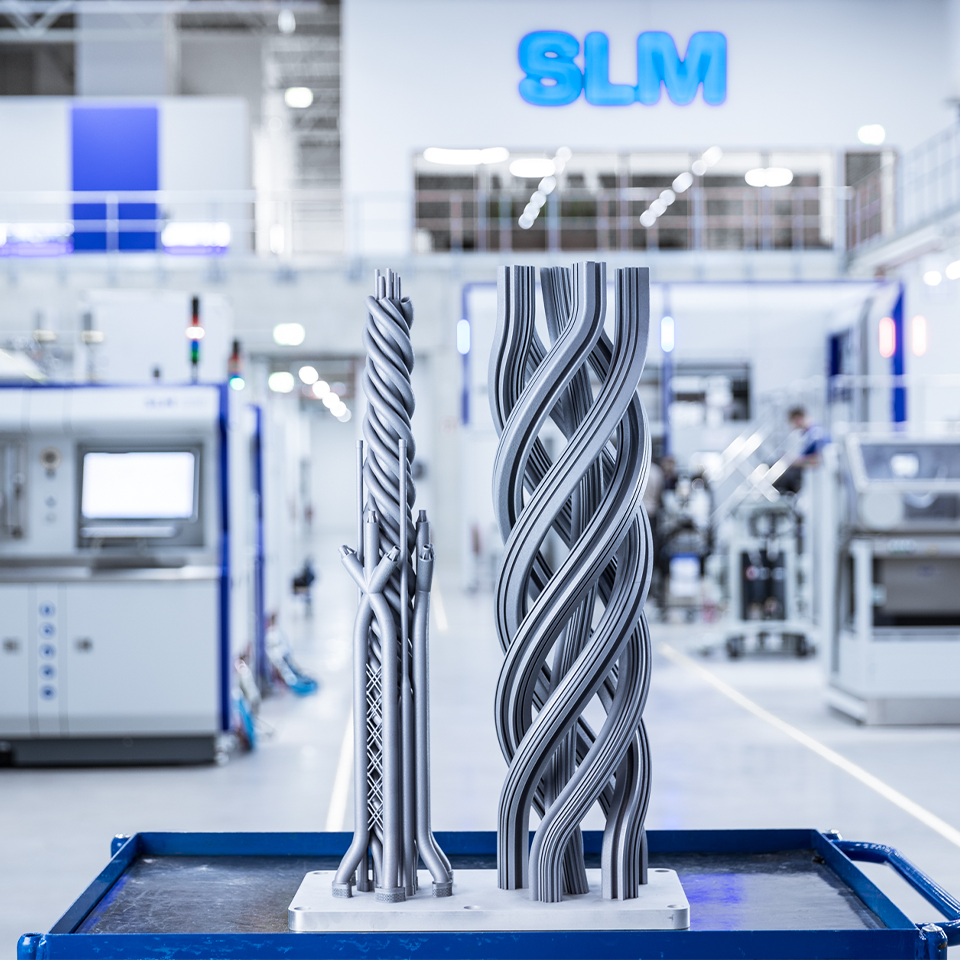

A physical 3D-printed part is the most convincing argument to experience the SLM® Quality.

You want to invest in additive manufacturing but still not sure if it´s suitable for you business model? Give us the chance to convince you! With more than 30 demo machines spread in global impressing Application Centers, we are ready to print your individual prototype.

We experience Benchmark Part Production as an ongoing learning curve and are always curious about current market needs. Our application engineering team welcomes you to discuss the different perspectives of process parameters, part design and powder qualification to find an individual solution for your additive business.

2. Production Service

During the last 10 years, SLM Solutions established numerous partnerships with qualified Additive Service Centers all over the world. If you are interested in part production as a jobshop, we are happy to share our long-term experience with you! By carefully analyzing your needs we will certainly find the right service provider for you part request. If your requirements concerning part quality are uncommon or you need a different metal powder for your part – don´t worry! Our application engineering team welcomes you to discuss the different perspectives of process parameters, part design and powder qualification to find an individual solution for your additive business.

3. Consulting

SLM Solutions is your one-stop additive manufacturing partner. We consult you in the right AM component design, part production and even help you to develop your factory concept. Get in touch with us for more information.

Training Offers

Need a refresher course, more in-depth information, or have a new operator in your 3D printing lab? Let SLM Solutions help reduce the learning curve of metal 3D by attending an additive manufacturing training session with our in-house team of experts. Training courses take place at our headquarters in Lübeck, Germany, at your facility, or at a location of your choice. We will create an individualized training to meet the needs of your process so you can enjoy access to the SLM Solutions team and our best-practices together with dedicated training without distraction.

Increase your success with selective laser melting.

Machine Services & Consumables

Our team offers experienced field service engineers around the world to ensure your system stays up and running at peak performance. From troubleshooting and repairs to preventative maintenance visits and remote support, our service department offers help when you need it. Service contracts are available for systems coming out of warranty, including preventative maintenance visits from our field service engineers, as well as support and upgrades with the option to include spare parts past your warranty. You can choose from Basic, Classic or Total care.

For more information on the different packages

Support Overview

We visit your installation site to check connections, building services, climatic conditions and access.

We care about the installation of your machine ensuring an optimal environment and commissioning.

After the installation of a machine, we conduct different acceptance test, standardized or individual.

We offer maintenance services to meet individual certifications in different industries.

We offer a worldwide Support Hotline, available 24/5 to keep your production running at any time.

Remote Service with a direct connection to the your machine is available to ensure technical support in each situation.

Spare & Wear Parts as well as original SLM® spare & wear parts

Original SLM® consumables and accessories

Retrofitting of technological innovations and system options

SLM Solutions provides a varity of powders and developed a specification and supply chain for a range of approved metal powders that ensure SLM® Systems produce components of consistently high quality time after time.

Financial Services*

SLM Solutions makes it possible and practical to keep your business competitive and your equipment on the cutting edge. Paying for your selective laser melting equipment with fixed, monthly payments allows you to preserve capital for other investments, and offers many additional benefits that make good business sense.

*Our financial services are aviable in selected markets only. Please contact us for your individual offer.

Your Benefits

- Improved cash-flow management

- Customized solutions that support your business goals

- Flexible terms and payment plans aligned with your budget

- Mid-term upgrades and add-ons to help protect against obsolescence

- End-of-lease options that accommodate changing business plans

- Master lease agreements to allow for growth and expansion

- Ability to bundle 100% of equipment, delivery, installation and maintenance fees under one contract

- Potential tax benefits

Special Offer

For a limited time only, SLM Solutions is offering two pricing advantages for North America clients:

No payments for 90 days: Couple deferred payments with low-interest rates on capital leases ($1 buyout) and Fair Market Value (FMV) structures with no money down.

-or-

0% interest: Enjoy 0% interest on capital leases ($1 buyout) plus deferred payments tailored to your business objectives