Automotive

Industrialization of Additive Manufacturing for Series Production of Vehicles

We support our customers to create their AM business case. The optimized topology AM part design for function and production enables OEM`s and Tier 1`s to reduce cost with maximized functionality. Additive Manufacturing could be the door opener for flexible production lines to adapt to customized car programs and shorter time frame model upgrades. The goal of metal AM in production is to be competitive to conventionally methods. To provide machine systems fulfilled industrial safety standard and helping in AM part manufacturer to certify their AM process according the automotive QS standard, like IATF 16949 is our vision.

SLM Solutions' expert application support helps to develop components optimized for Selective Laser Melting, from prototype to production. See below the numerous possibilities for the automotive industry.

“SLM Solutions is a powerful, long-term strategic partner for Divergent 3D, working with us to provide 3D metal printing hardware and software specific to the Divergent Manufacturing Platform™. We believe that this will transform the way vehicle structures are designed, engineered, manufactured and assembled.”

Kevin Czinger, CEO of Divergent 3D

Selective Laser Melting Solutions for Automotive Applications

Success Story

Active Heat Shield of Bugatti

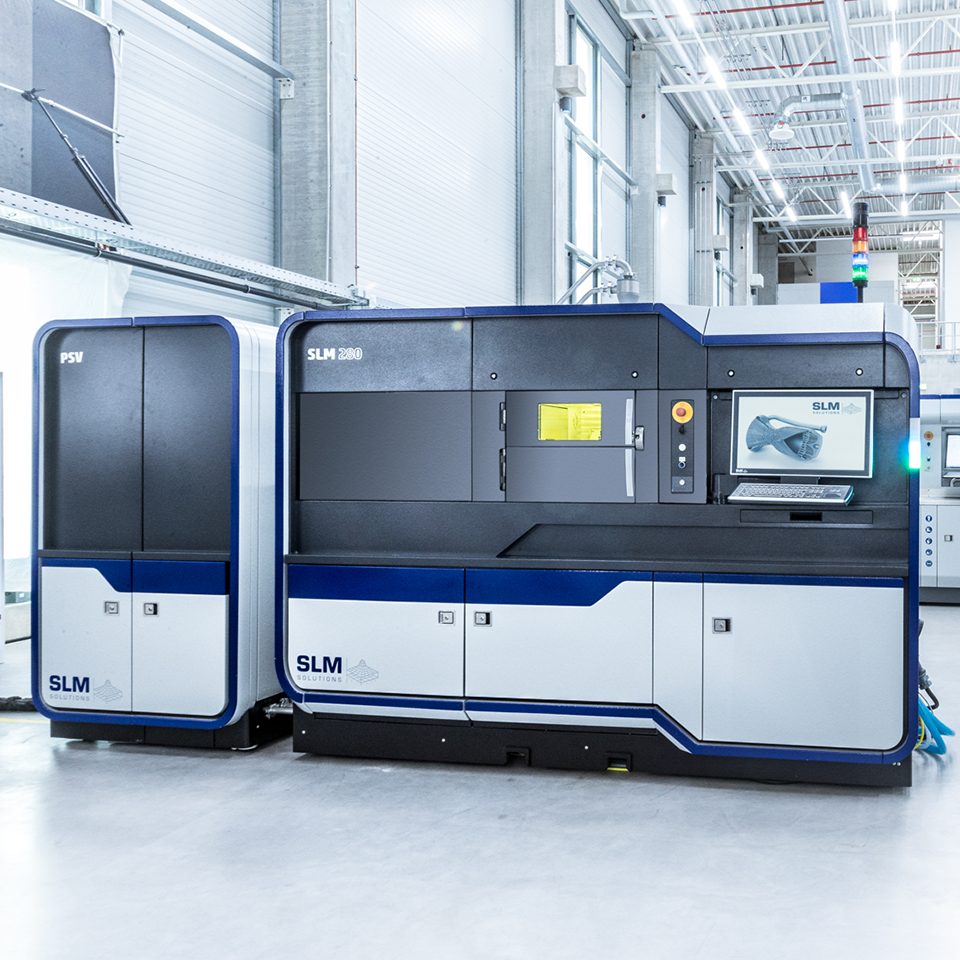

Printed on: SLM®280 Twin

Material: AlSi10Mg

Layer Thickness: 60µm

Build Time: 4 hr 4min per part

Installed in all vehicles since the delivery of the first Bugatti Chiron from the production facility in Molsheim this part provides integrated water-cooling channels to act as an active heat shield to motor's electric pump. The complex geometry was produced at lower costs than with traditional methods.

Success Stories

Automotive Steering Knuckle from Hirschvogel Tech Solutions

Printed on: SLM®500 Quad

Material: AlSi10Mg

Layer Thickness: 60 µm

Build Time: 2d 7h 23min (full load, 1 piece)

The part development of this car steering knuckle of Hirschvogel Tech Solutions is based on an integrated approach taking the entire additive manufacturing process chain into account. This part combines a high level of development expertise in lightweighting, as well as in the application of designs based on bionics, achieving a 40% weight saving in the neck area compared to the conventional forged part. Production requires few support structures leading to reduced post-processing effort.

Success Stories

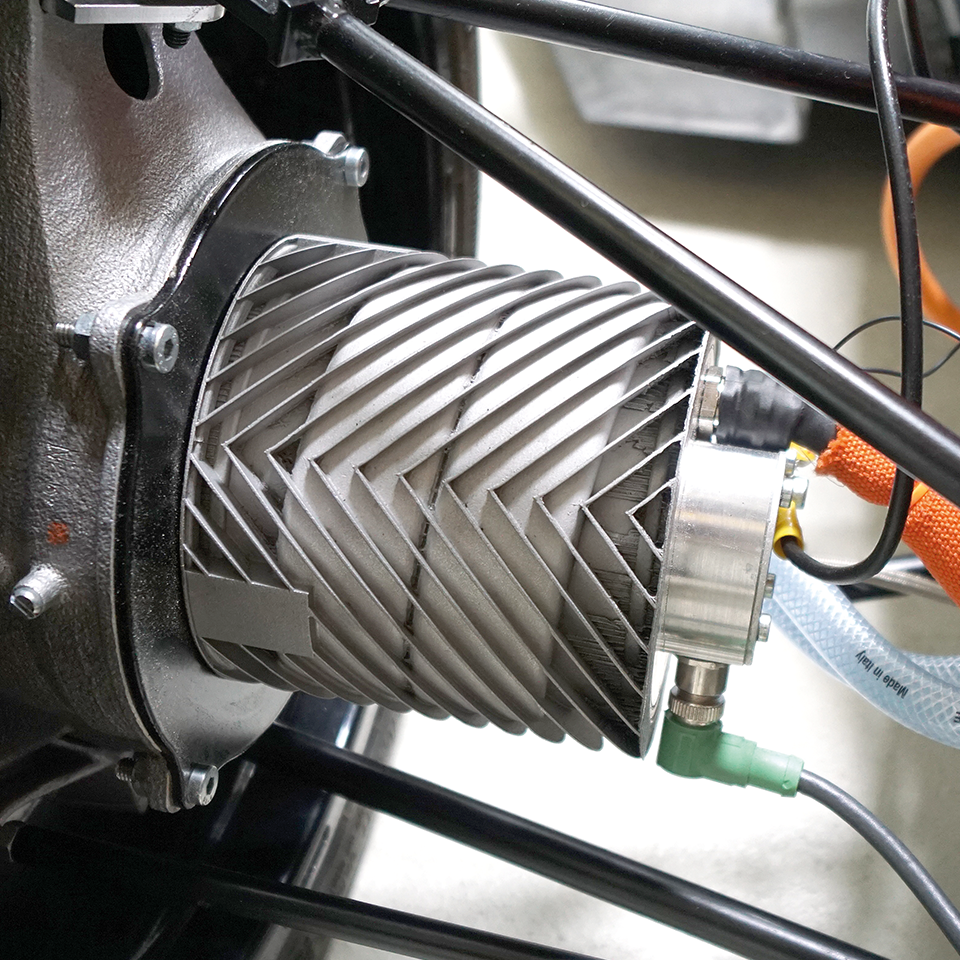

Motor Housing for an Electric Race Car from Lions Racing Team

Printed on: SLM®280 Twin

Material: AlSi10Mg

Layer Thickness: 30µm

Build Time: 20h 1min (full load 4 pieces)

The Lions Racing Team of Braunschweig University of Technology additively manufactured a motor housing for an electric race car. The robust aluminum construction improves connection strength and cooling capacity while increasing performance in cooling capacity through additive design.

Success Stories

Bugatti Brake Caliper

Printed on: SLM®500

Material: Ti6AL4V

Sparks fly during the dynamic bench testing of this brake caliper of Bugatti. The volumetrically largest functional titanium component built with selective laser melting has been tested by Bugatti. The additively produced metal part can cope with extreme strength, stiffness and temperature requirements at speeds. Caliper test showed tensile strength of 1,250 N/mm2 and material density over 99.7%. The part was manufactured with Fraunhofer IAPT (formerly Laser Zentrum Nord) and Bionic Production AG.

Recommended SLM® Machine For Automotive Applications

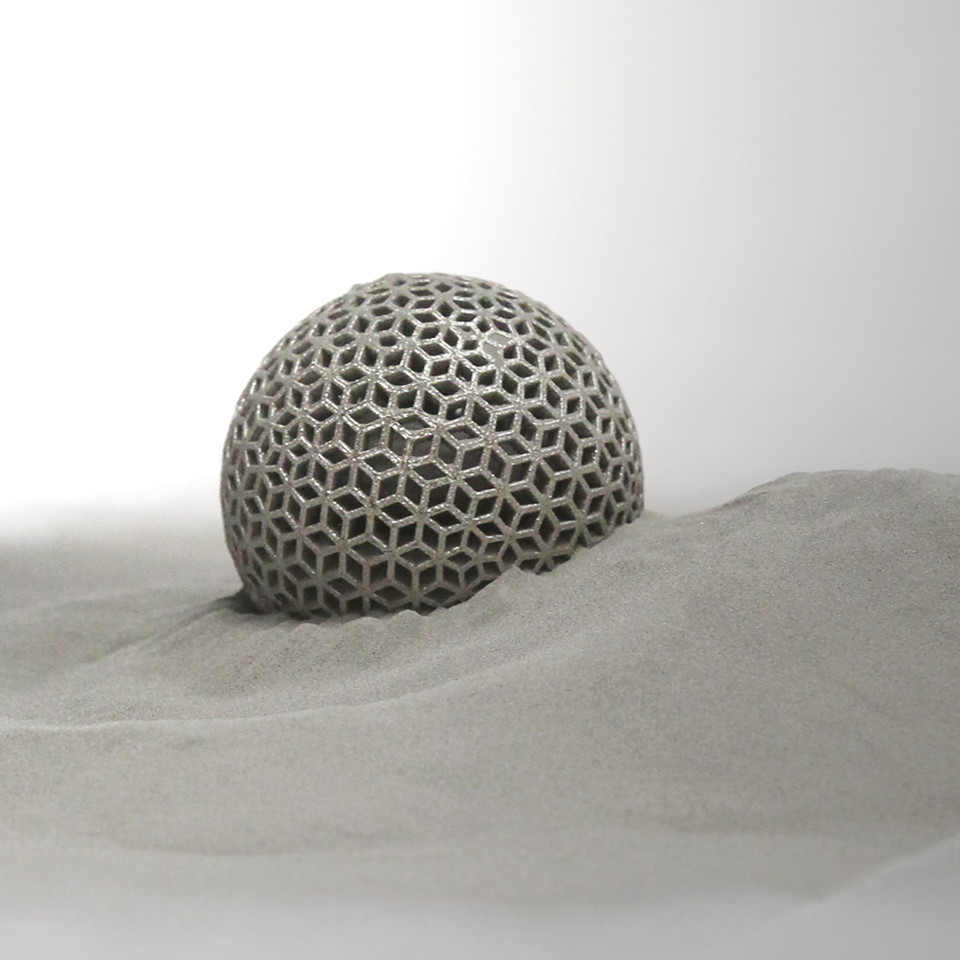

SLM® Material for Automotive Applications

SLM Solutions sells appropriate powder and parameter sets for the most common powders in the automotive industry:

- Al-Based Alloys: AlSI10Mg, ALSi7Mg and AlSi9Cu3

- Ni-Based Alloys: Inc. 625

- Fe-based Alloys: 1.2709, 316L (1.4404)

Within several development projects, SLM Solutions also works on parameter sets for new AM alloys. If you have any questions or need expert application support for cost comparison study, feasibility check, risk analysis and simulation including design modification or quality check of printed parts with industrial high technical standard equipment - contact us.