Aviation and Aeronautics

3D Printing Solutions for Your Aerospace Application

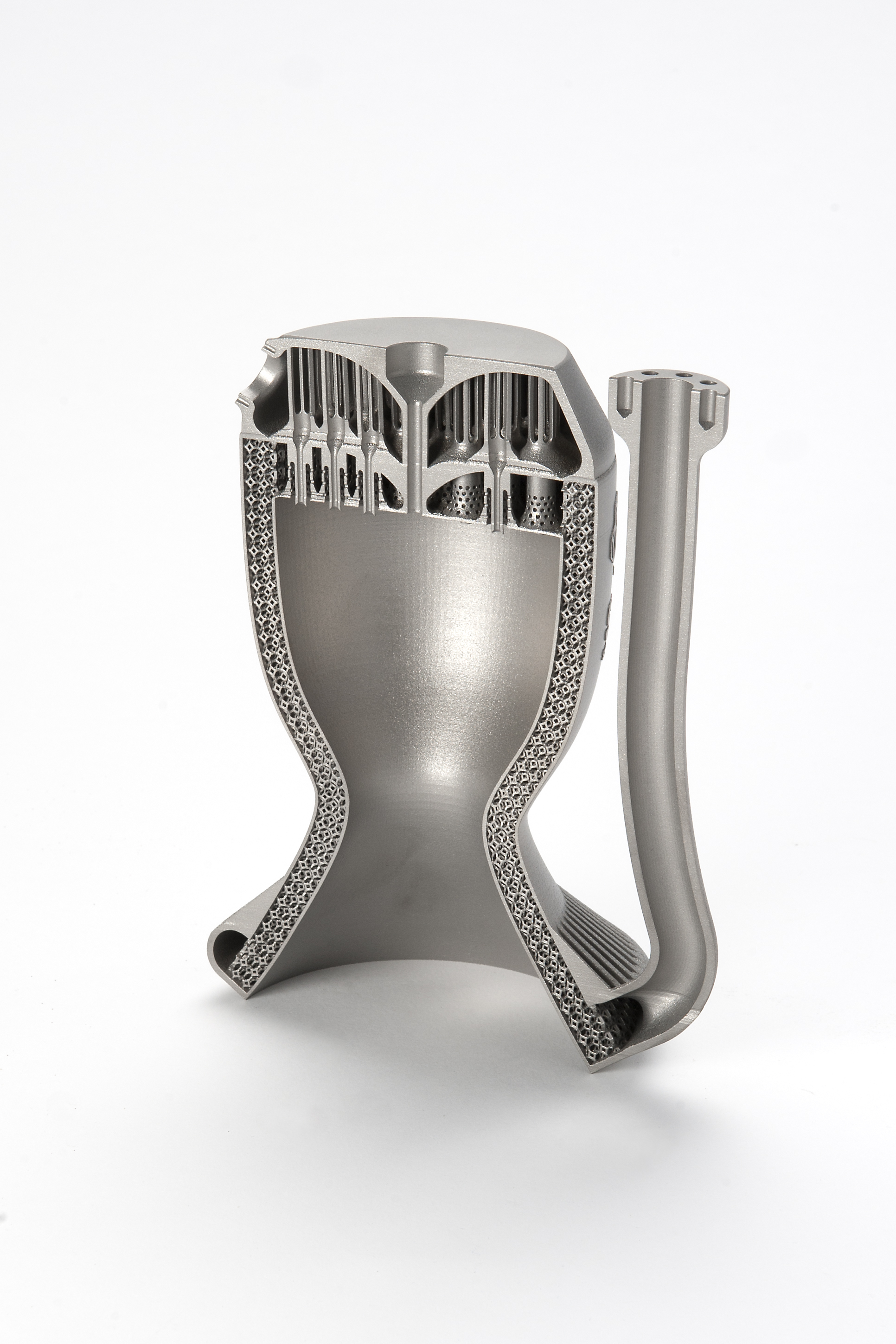

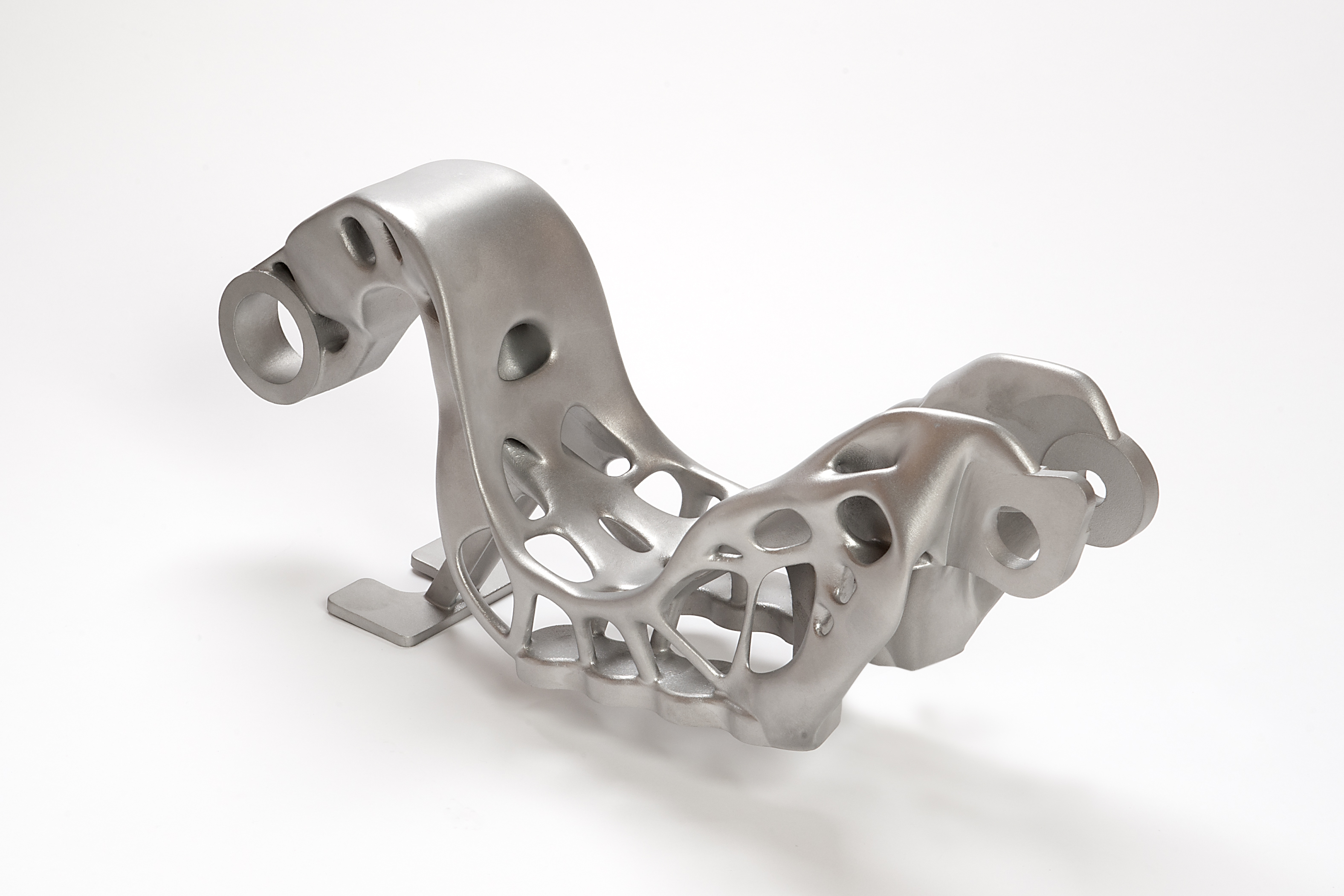

You think about 3D printing metal parts for your aerospace application? Selective Laser Melting helps you to improve performance of metal parts, fastens up development cycles due to tool-less production and finally can reduce your costs in comparison to traditional manufacturing methods.

Whether your objective is to print prototypes or certified flightworthy parts – we help you to get successful with additive manufacturing. Find out more about the numerous manufacturing possibilities using SLM® technology in the aerospace industry below.

Selective Laser Melting Solutions for Aerospace Applications

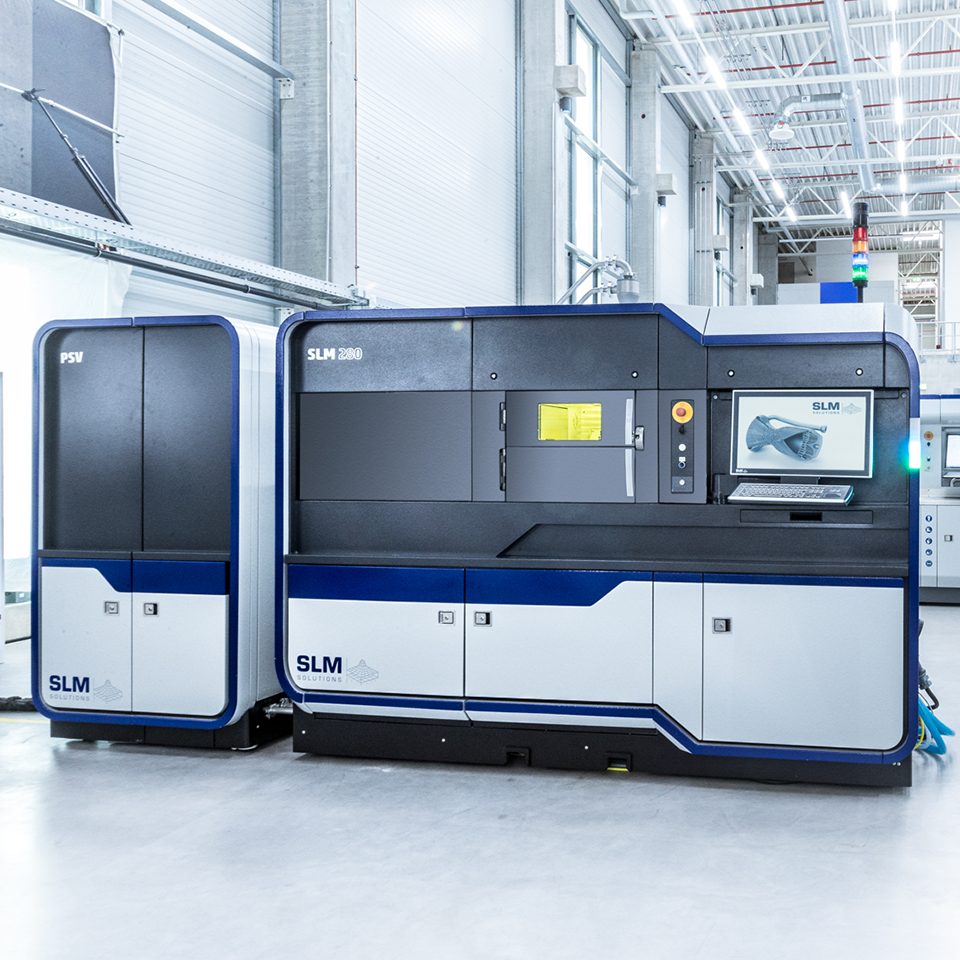

Recommended SLM® Machine For Aerospace Applications

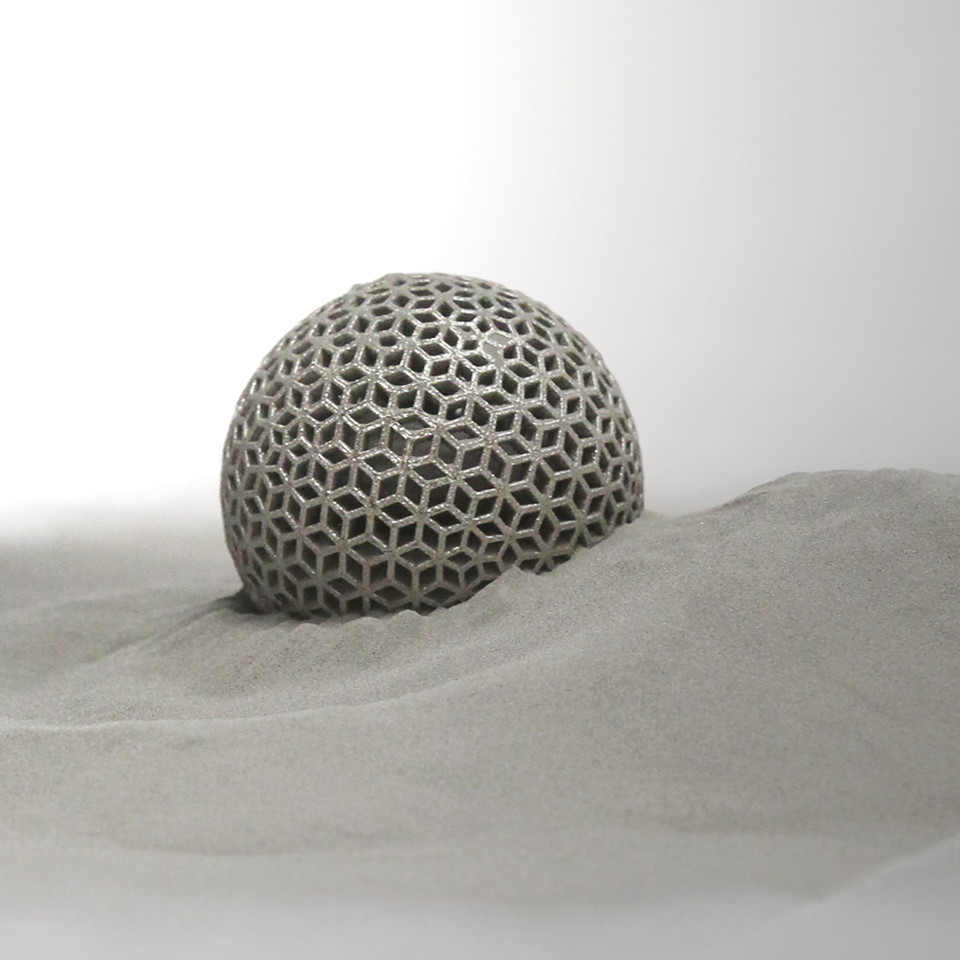

Recommended Material

SLM Solutions provides a wide range of suitable materials for the aerospace industry which meet the stringent requirements of aircraft engine manufacturers for metallographic and mechanical properties.

Our portfolio includes:

- Ni-Based Alloys: IN625, IN718 and HX

- Ti-Based Alloys: TIAl6V4

- Al-Based Alloys: AlSi10Mg

Quality Standards for Aerospace Industry

We are experts when it comes to qualification of metal parts and our machines and help you at each stage of the process. SLM Solutions supports aerospace projects with relevant documentation, certificates, pFMEAs, parameters, powders, aero-space tailored services and more. Contact us and let's share our knowledge with you to boost your metal additive manufacturing production.