Energy

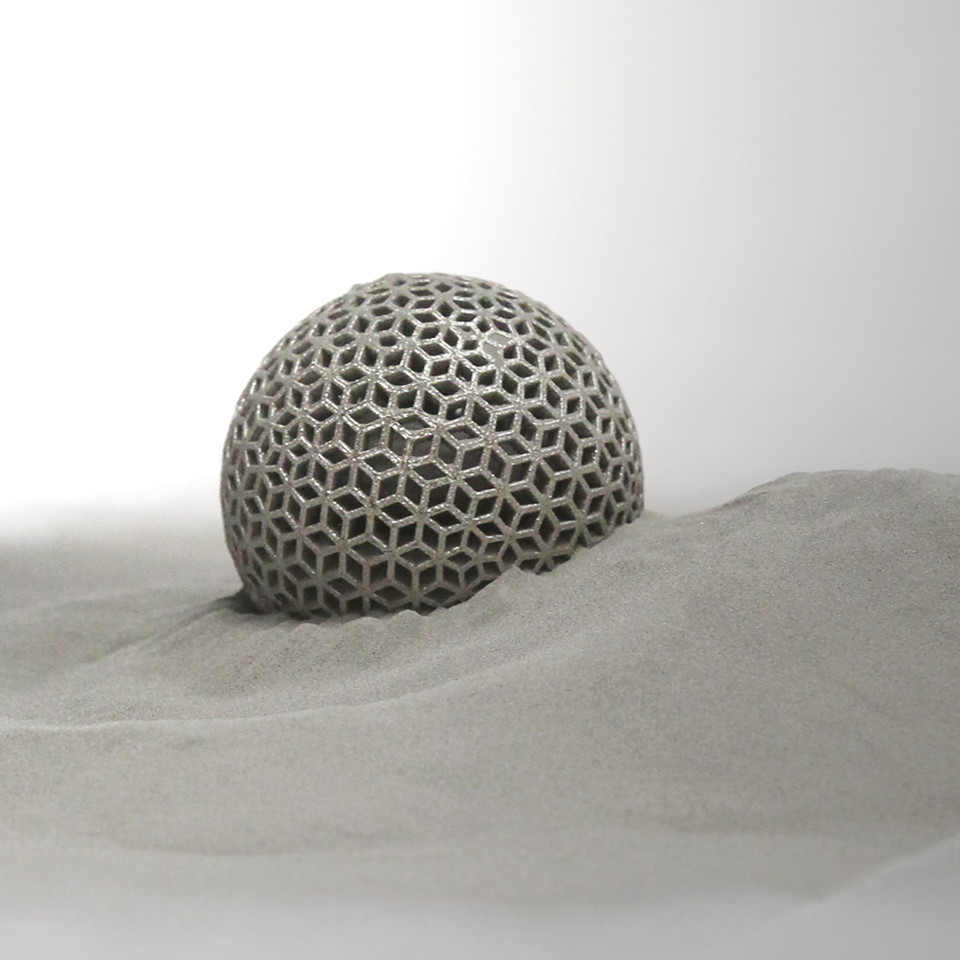

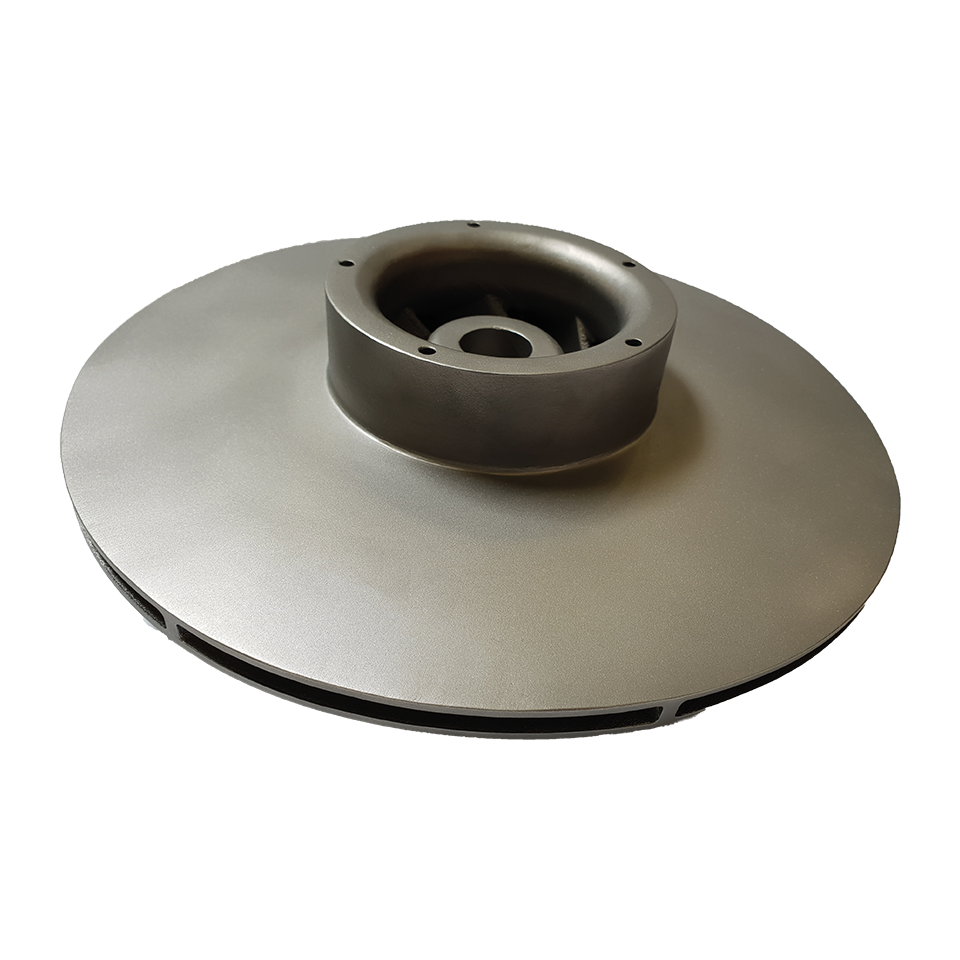

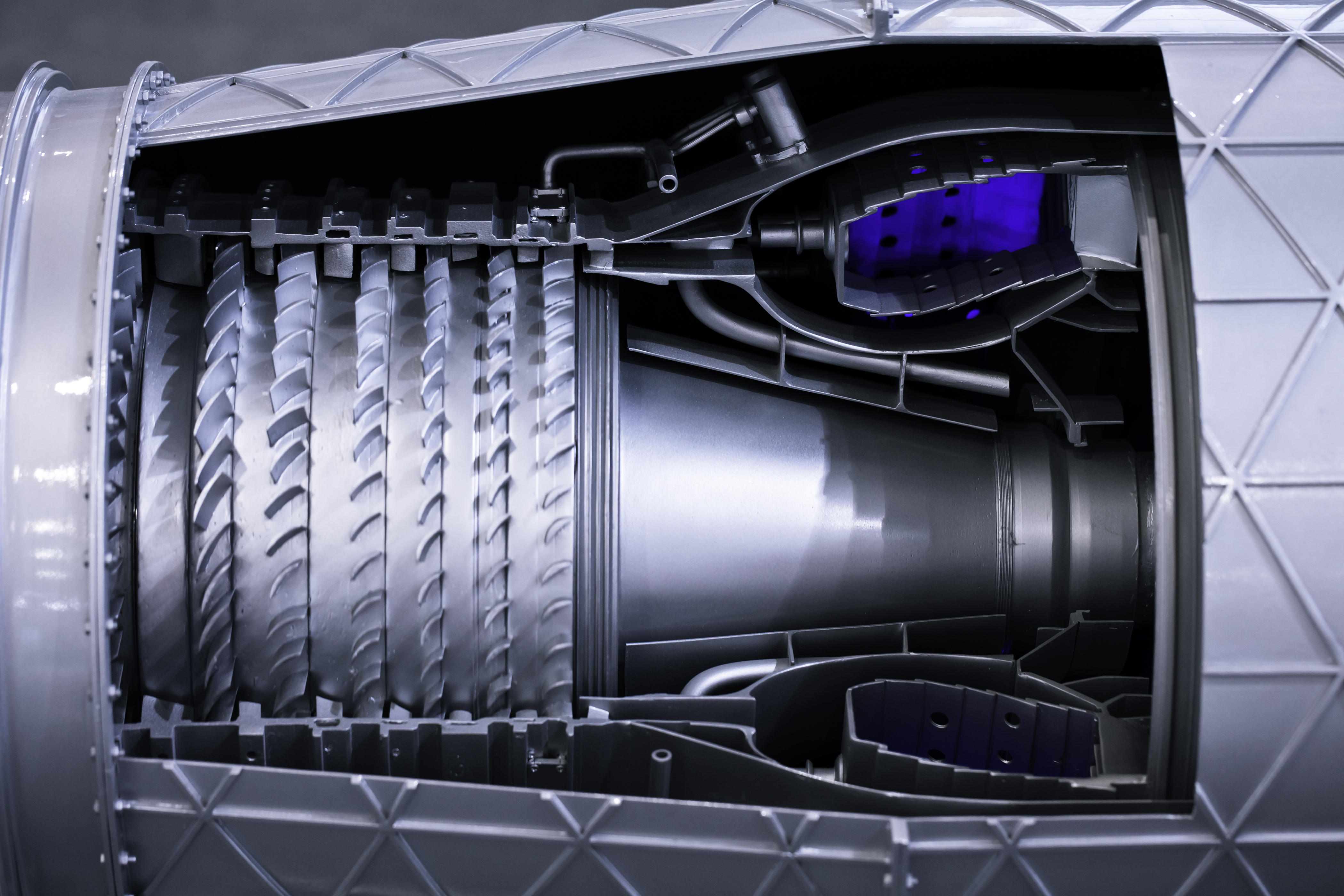

Advantages of 3D Printing for Energy

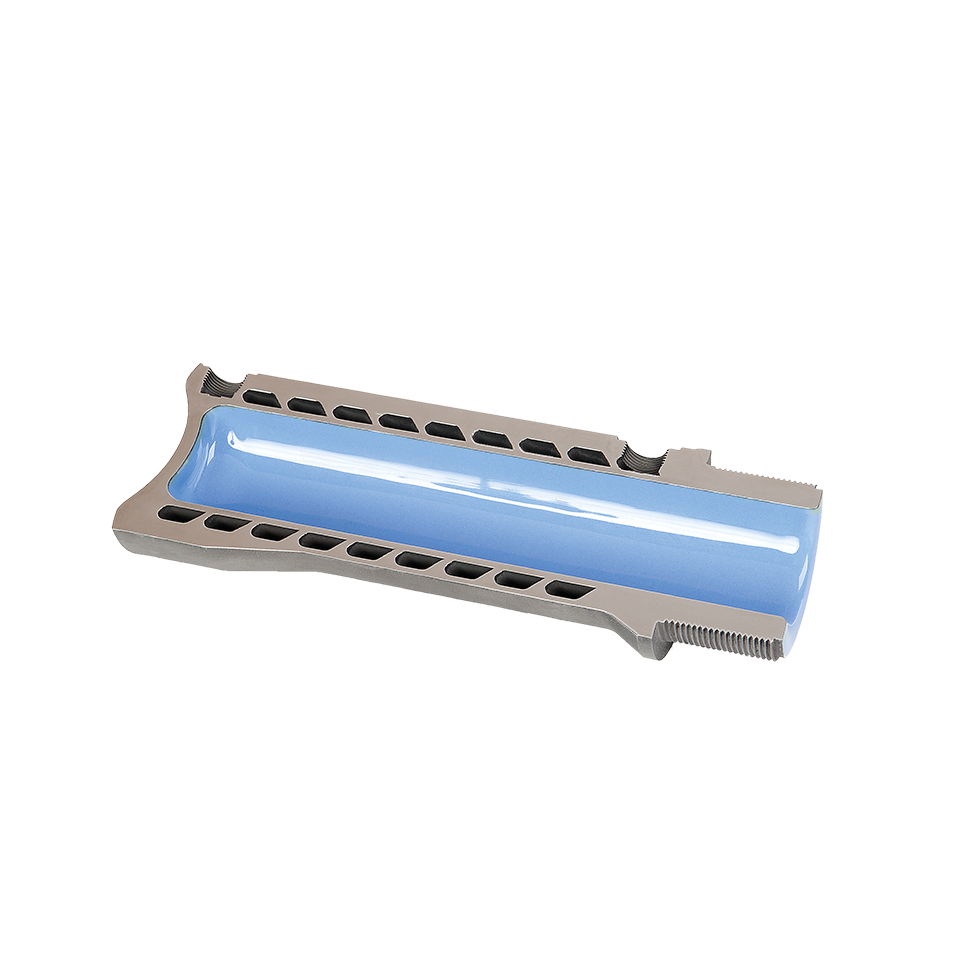

The energy industry is characterized by a significant high level of customization in its asset. Therefore, the yearly production volume falls in the range of hundreds or rather thousands parts per year each design. Such volume is on the left-low cost effective capacity range of investment casting and forging while it fits perfectly in the highest cost efficiency point for additive manufacturing. Avoidance of tooling, full design flexibility and immediate production planning redefinitions are key enabler of a smart and lean supply chain.

The traditional business model of energy operators contemplate a huge immobilized capital of spare parts, because of procurement lead time and asset downtime cost. AM is measuring parts production and delivery into days - vs. weeks or months - enabling the most efficient just-in-time production scenario. Moreover, thanks to its flexibility it allows efficient production close to the point of use eliminating transportation, duties delays and increasing local content.

Selective Laser Melting Solutions for Energy Applications

Recommended SLM® Machine For Energy

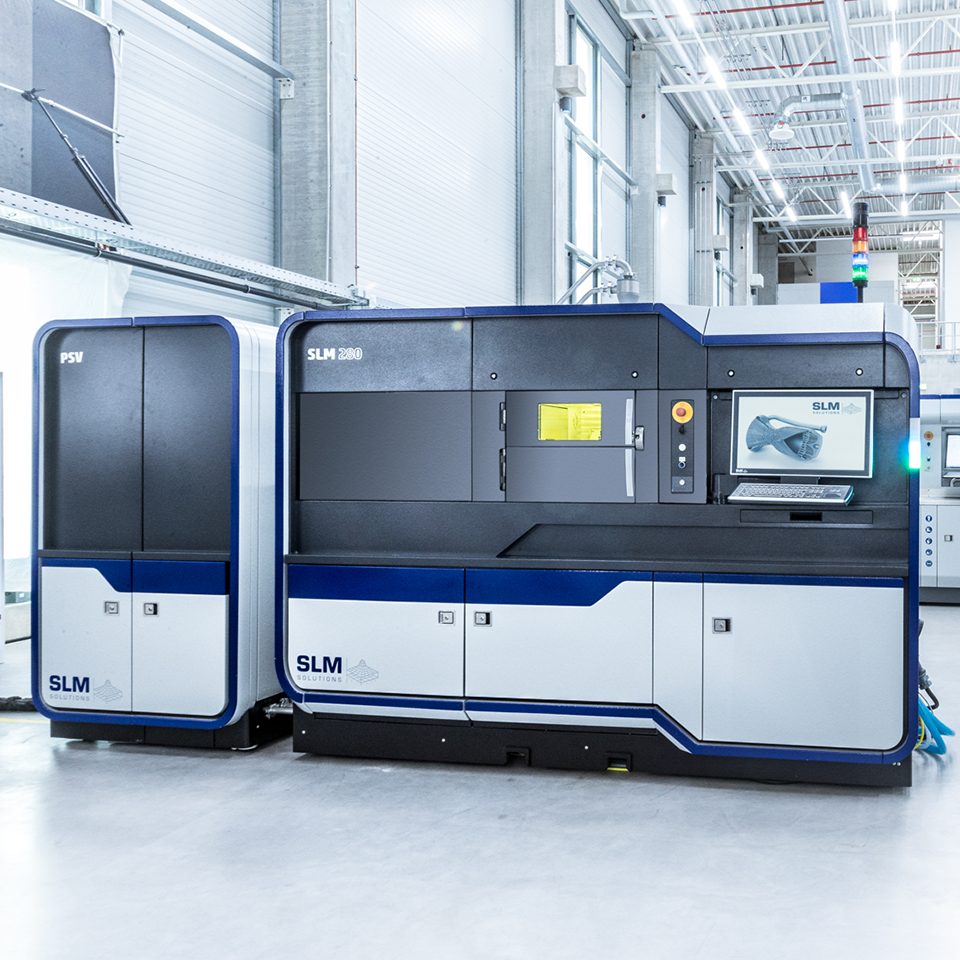

SLM®280 Production Series

The SLM®280 Production Series targets the serial production processes with fully automatic powder management in inert gas atmosphere and provides a patented, enhanced gas flow that creates a clean process environment and increase build quality. A permanent filter module additionally increases machine uptime and safety.

SLM®500

The SLM®500 system is optimized for the serial production of high volume projects. Safety and material quality are increased through closed loop powder handling and a part removal station for efficient unpacking additionally increases machine downtime.

SLM®800

With an extended z-axis, the SLM®800 is suitable for the large-scale production of parts with up to 850mm height. Up to five machines can be connected to one SLM®HUB, SLM Solutions' fully automatic handling station.

SLM® Material for Energy Applications

SLM Solutions sells appropriate powder and parameter sets for the most common powders in the energy industry:

- Ni-Based Alloys: IN625, HX, IN718, IN939

- Fe-Based Alloys: 316L (1.4404)

- Cu-Based Alloys: CuSn10

Within several developemt projects we also work on new parameter sets for new materials. If you have any questions to your individual material solution, feel free to contact us.