Healthcare

Advantages of Additive Manufacturing for Healthcare

Qualified serial production of surgical implants, medical devices and dental prostheses

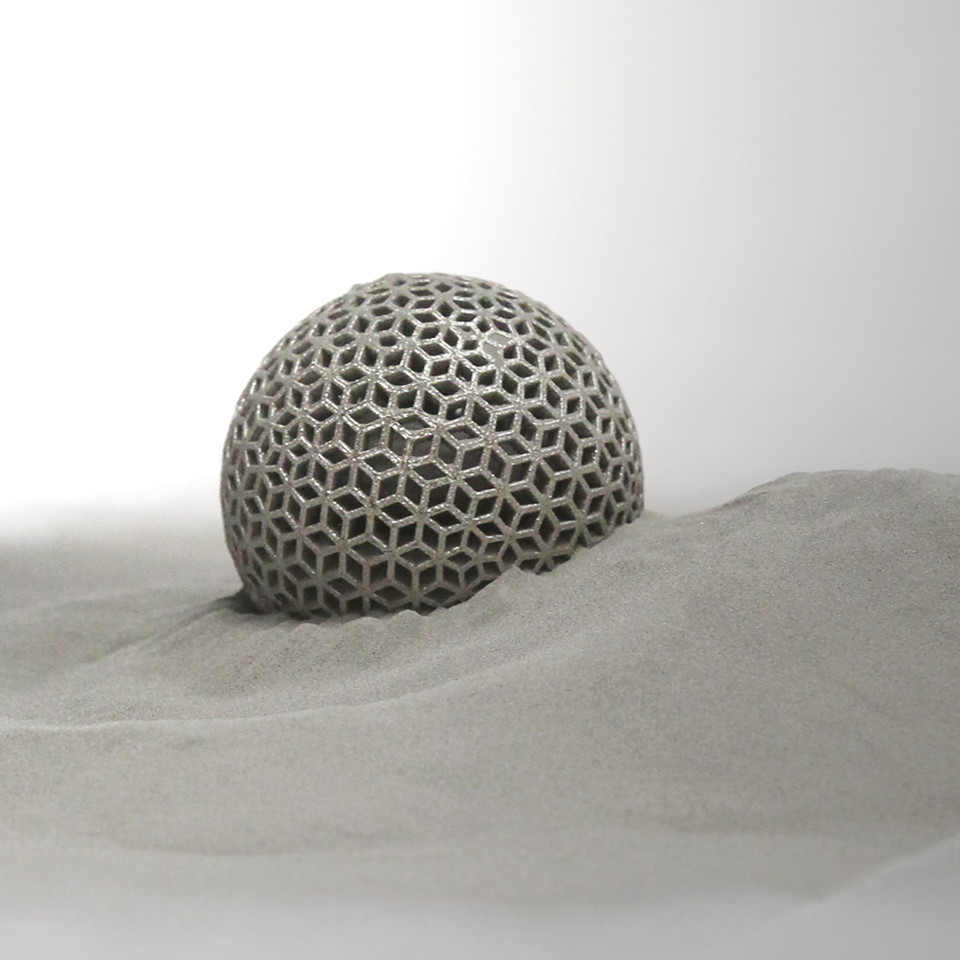

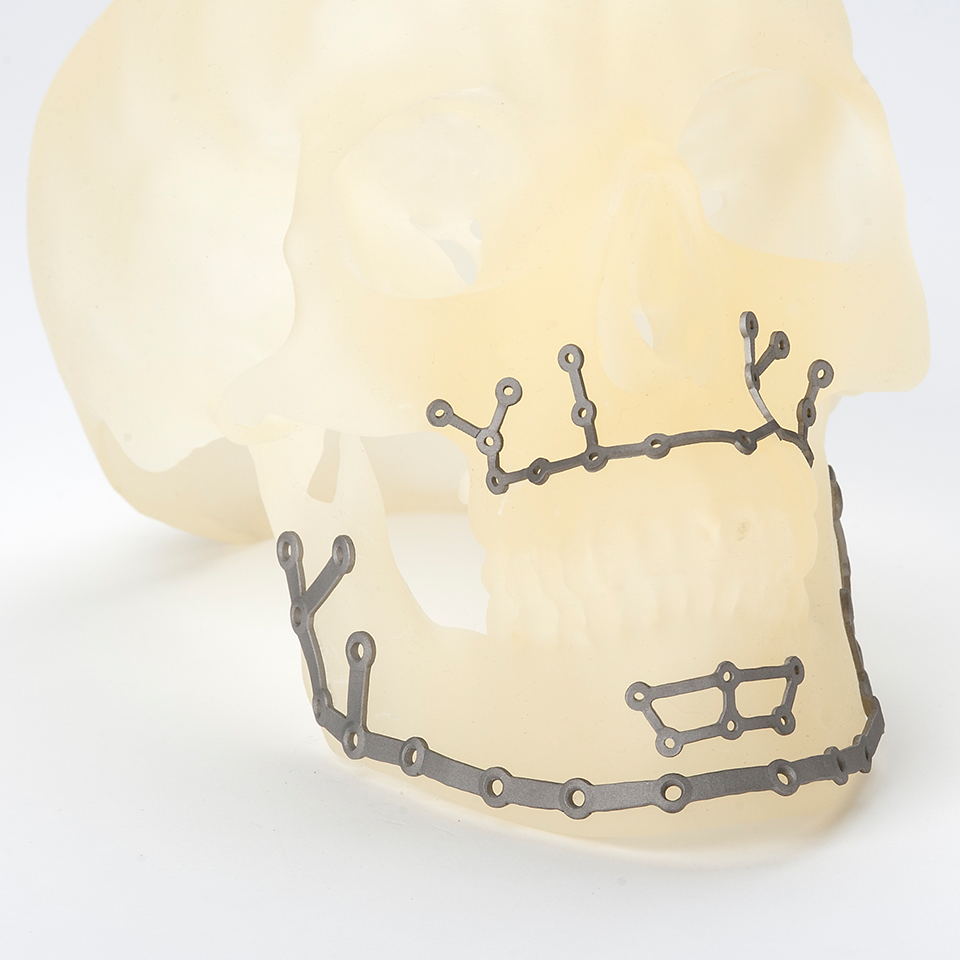

Medical device manufacturers are increasingly adopting metal additive manufacturing technology to produce a wide range of medical devices and dental prostheses. Selective laser melting is the ideal production technique to integrate function into medical device components, e.g. printing surgical implants with lattice structures for enhanced osseointegration and reduced stress shielding. Designs optimized for the SLM® process, and those custom to patients’ anatomy, often create complex bionic geometries which can only be efficiently produced with selective laser melting. The SLM® technology provides productivity and cost advantages to users, compared to conventional manufacturing processes such as casting and machining.

Selective Laser Melting Solutions for Healthcare Applications

Recommended SLM® Machines For Healthcare

SLM®125

The SLM®125 machine offers high-powered laser in a compact footprint for flexible manufacturing to fit your specific needs.Being the smallest machine in SLM Solutions portfolio it still offers the same top quality features of larger machines providing highest safety, quality and flexibility.

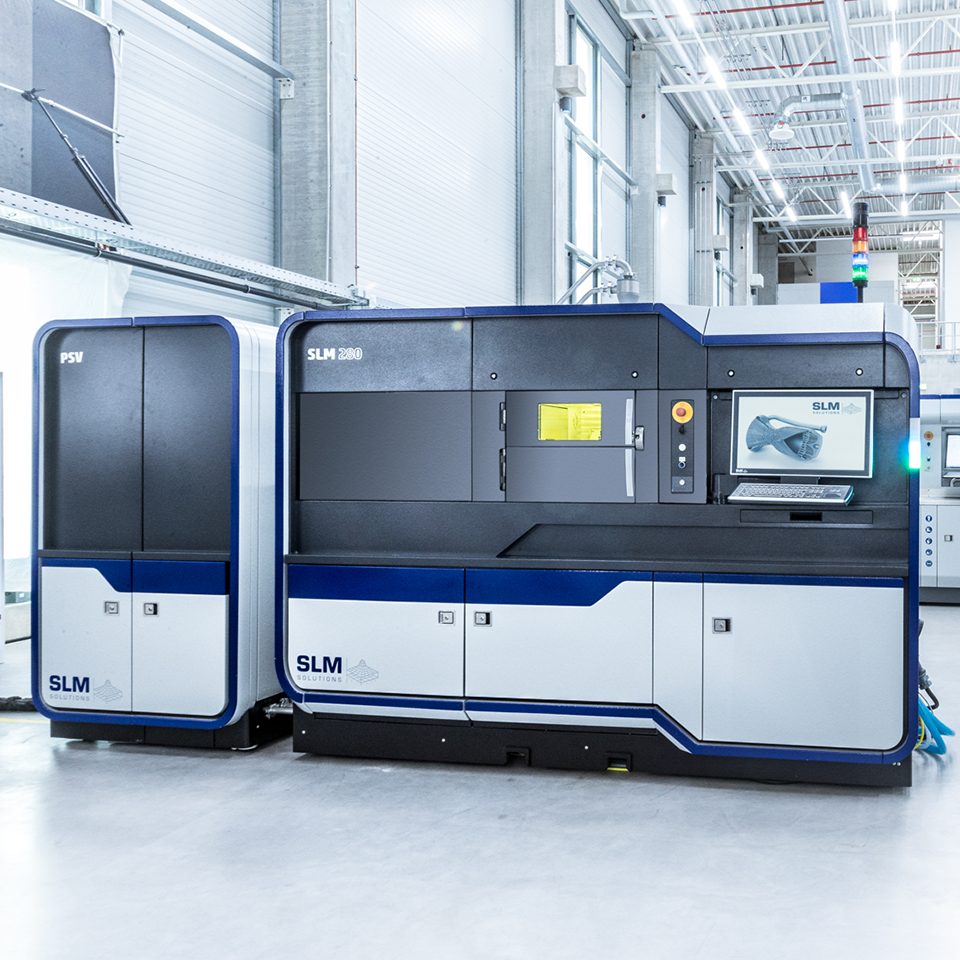

SLM®280 2.0

The SLM®280 2.0 provides optimum material quality and is particularly suitable for prototyping or small production series. Paired with a Powder Sieving Machine (PSM), the machine offers high material flexibility. Manual sieves allow efficient material changeover for adaptable production while maintaining safety and quality. Equipped with patented multi-beam technology and bi-directional recoating it helps shorten production times.

SLM®280 Production Series

The SLM®280 Production Series targets the serial production processes with fully automatic powder management in inert gas atmosphere and provides a patented, enhanced gas flow that creates a clean process environment and increase build quality. A permanent filter module additionally increased machine uptime and safety.

SLM® Materials for Healthcare Applications

SLM Solutions offers a wide range of qualified metal powders for use on our selective laser melting systems and commonly utilized in the healthcare industry. All materials provided by SLM Solutions are qualified for their chemistry, spherical structure, particle size distribution, dryness and flowability. We offer validated process parameters for all biomaterials on all our machines.

- Ti-Based Alloys: Ti6Al4V Gd. 23, Ti (Grade 2)

- Co-Based Alloys: CoCr28Mo6, SLM® MediDent

- Stainless Steel: 316L (1.4404), 17-4PH (1.4542)

This is not what you are looking for? Other biomaterials are available on request.