Research

Selective Laser Melting Technology For Research Applications

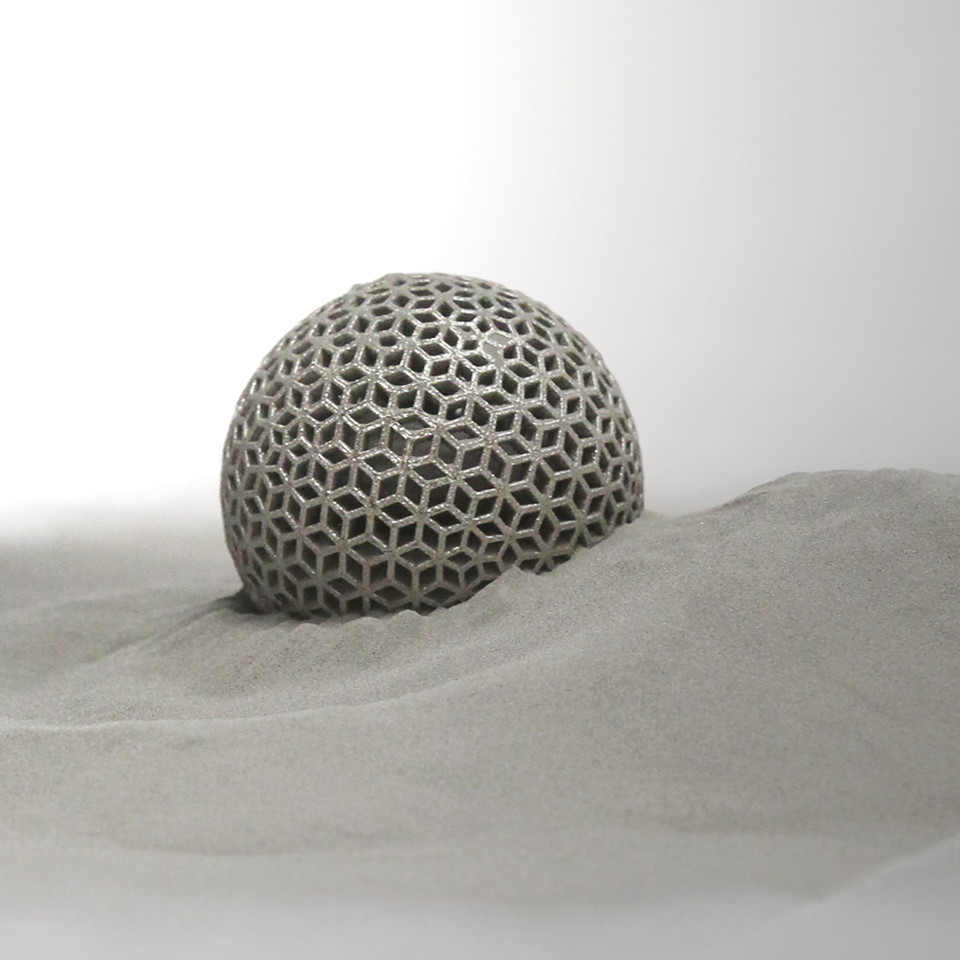

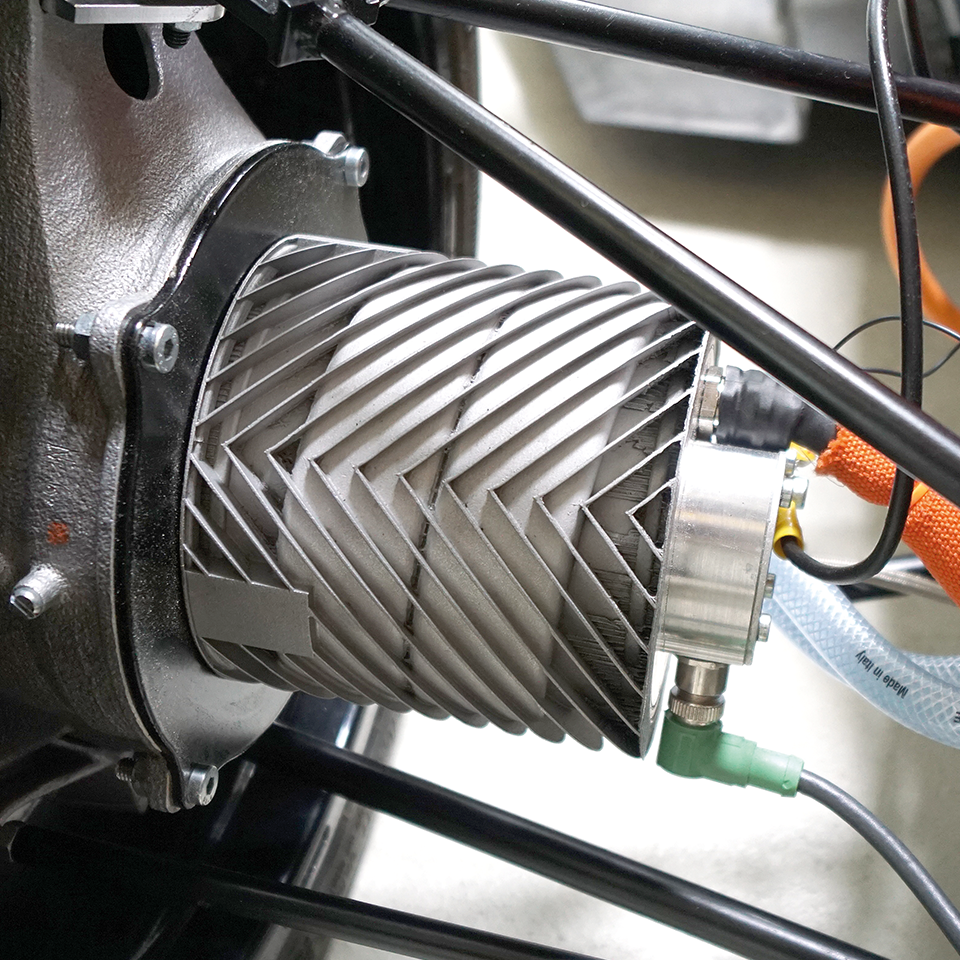

SLM Solutions partners with various universities, institutes of technology and research centers to advance the science of laser powder bed fusion for metals. Design for additive manufacturing, topology optimization, lightweighting, functional integration, new alloy development, advanced production techniques are just a few of the R&D and teaching activities our Research customers are engaged in.

The unique open architecture of our selective laser melting systems provides the user with full control over all process parameters, enabling an efficient optimization of the selective laser melting process both for new alloy formulation and for the development of new engineering applications. All our machines are equipped with a unique material development module which puts the user in full control of process parameter optimization in an efficient manner, when needed. Explore how metal additive manufacturing from SLM Solutions can enhance your research and development capabilities.

Key Benefits for Your Research & Development

Test New Material Solutions

Selective Laser Melting Machines of SLM Solutions provide the ability to efficiently test new powders with minimal usage!

Open Parameter System

We grow with your ideas and business. Our open parameter systems allow for experimentation and refinement of processes.

Your freedom in the choice of powder

We give you the freedom to develop! Open source powder system runs powders from any supplier.

Material Development Module

Our material development module is an easy, intuitive software tool for a systematic analysis of parameter variation. Users gain the power of developing in-house material know-how and utilizing custom process settings.

Recommended SLM® Machines For R&D

SLM®125 machine

The SLM®125 machine offers high-powered laser in a compact footprint for flexible manufacturing to fit your specific needs. Being the smallest machine in SLM Solutions portfolio it still offers the same top quality features of larger machines providing highest safety, quality and flexibility.

SLM®280 2.0

The SLM®280 2.0 provides optimum material quality and is particularly suitable for prototyping or small production series. Paired with a Powder Sieving Machine (PSM), the machine offers high material flexibility. Manual sieves allow efficient material changeover for adaptable production while maintaining safety and quality. Equipped with patented multi-beam technology and bi-directional recoating it helps shorten production times.

SLM®500

With its larger build envelope featuring 500 x 280 x 365 mm, the SLM®500 system is optimized for high volume projects. Safety and material quality is increased through a closed loop powder handling while a part removal station for efficient unpacking increases machine downtime.

SLM® Materials for R&D Solutions

SLM Solutions offers a wide range of qualified metal powders for use on our selective laser melting systems and commonly utilized in Research. All materials provided by SLM Solutions are qualified for their chemistry, spherical structure, particle size distribution, dryness and flowability. We offer validated process parameters for all our metal powder materials on our machines. We also support our customers with the development of new alloys.

| Aluminium Alloys | AlSi10Mg, AlSi7Mg0.6, AlSi9Cu3 |

| Titanium Alloys | Ti6Al4V ELI (Grade 23), TA15, Ti (Grade 2) |

| Nickel Alloys | HX, IN625, IN718, IN939 |

| Tool and Stainless Steel | 316L (1.4404), 15-5PH (1.4545), 17-4PH (1.4542), 1.2709, H13 (1.2344), Invar 36® |

| Cobalt Alloys | CoCr28Mo6, SLM® MediDent |

| Copper Alloys | CuSn10, CuNi2SiCr |