Tooling

Advantages of Additive Manufacturing for Tooling

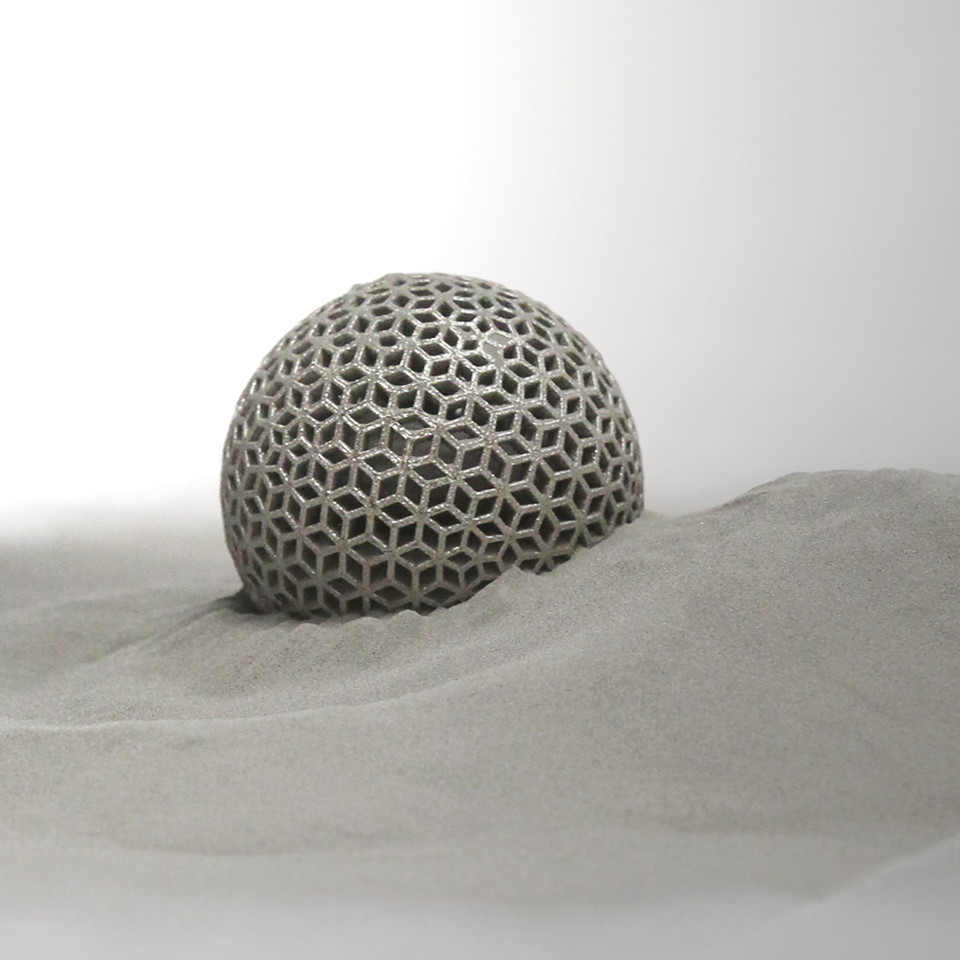

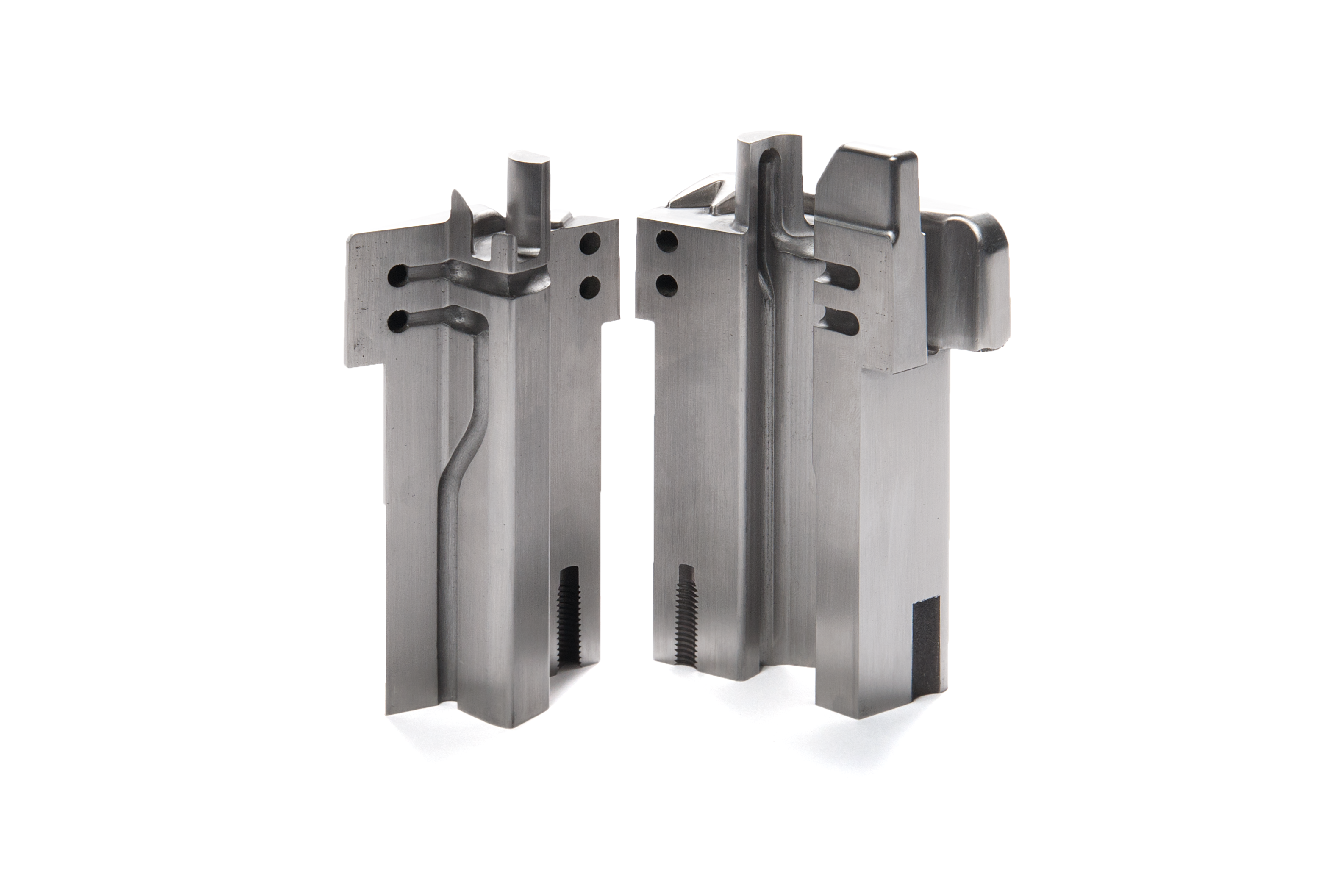

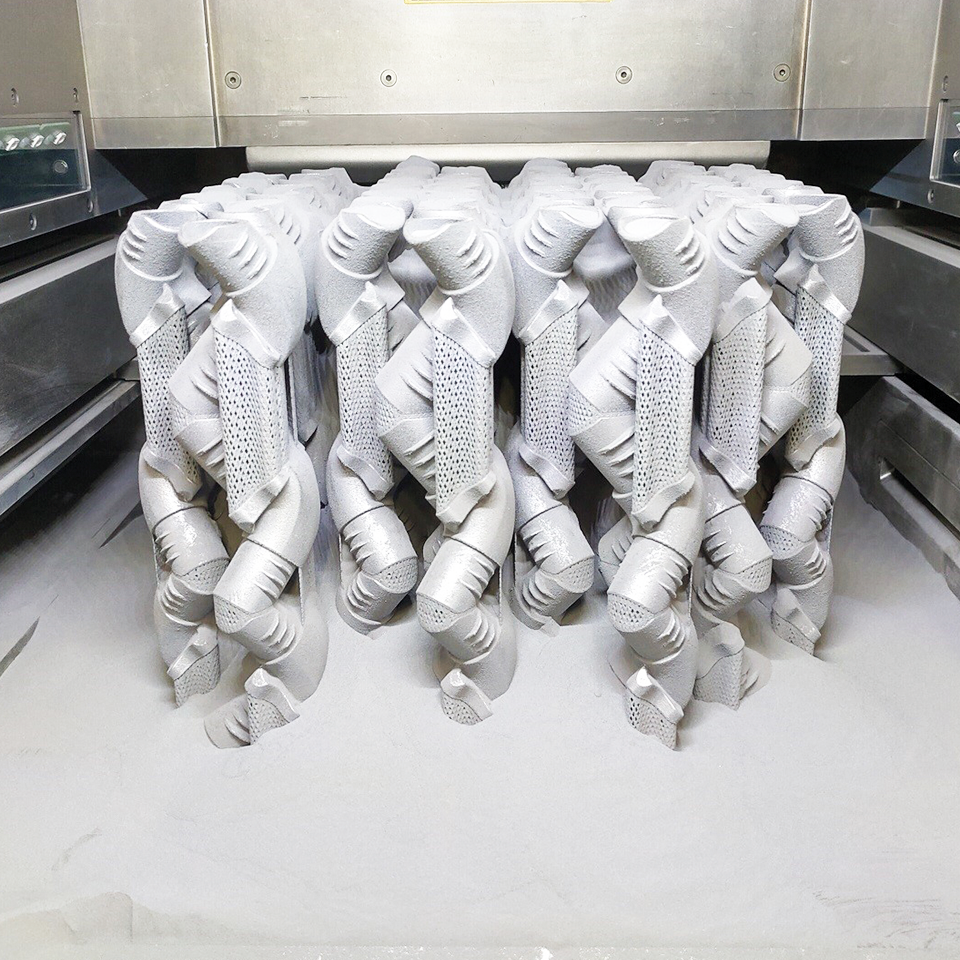

With metal AM technology, molds for thermoplastic, rubber or die cast as well as hot stamping tools with shaped cooling channels can be manufactured. SLM® technology reduces the cycle time up to 75% and creates higher product quality of the parts manufactured with the molds; production efficiency is improved. Metal printed fixtures and gauges with customized design enhance production line for higher productivity and safety assembly.

Expert applications support from SLM Solutions aids in developing components optimized for selective laser melting, from prototype to production

Selective Laser Melting Solutions for Tooling

Recommended SLM® Machine For Tooling

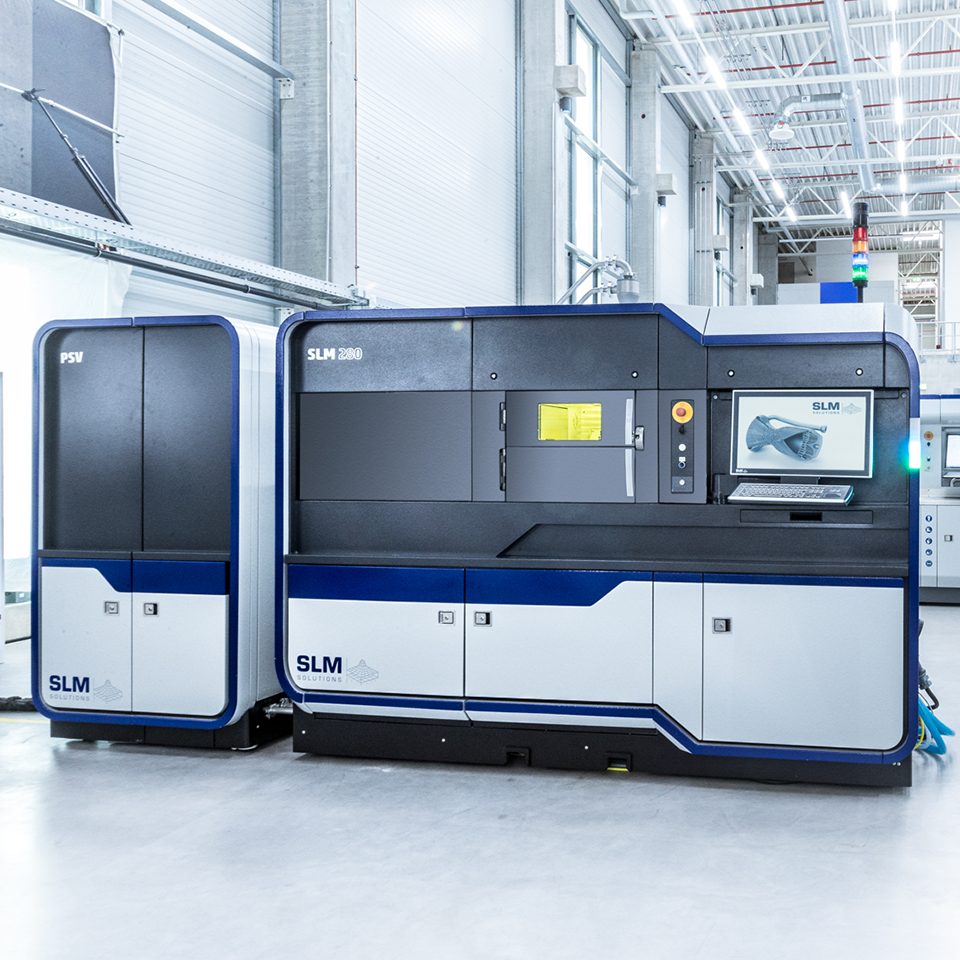

SLM®280 Production Series

The SLM®280 Production Series provides a patented, enhanced gas flow that creates a clean process environment and increase build quality. A permanent filter module additionally increases machine uptime and safety. Powder transport, sieving and storage is contained within an inert gas atmosphere to maintain material quality.

SLM®280 2.0

SLM®280 2.0 offers excellent material flexibility and easy material changeovers. Combined with SLM Solutions’ multi-laser technology and bi-directional recoating the machine is optimal suited for prototyping. Once prototyping is finished the project can be easily transferred to other SLM® machines like the SLM®500 or SLM®280 PS for serial production.

SLM® Materials for Tooling Applications

SLM Solutions offers a wide range of qualified metal powders for use on our selective laser melting systems. All materials provided by SLM Solutions are qualified for their chemistry, spherical structure, particle size distribution, dryness and flowability.

- Fe-Based Alloys: 316L (1.4404), 1.2709, H13 (1.2344)

- Co-Based Alloys: CuNi2SiCr